New, Versatile Infrared Oven Ensures brilliant Surface Finish For Kitchen Fronts

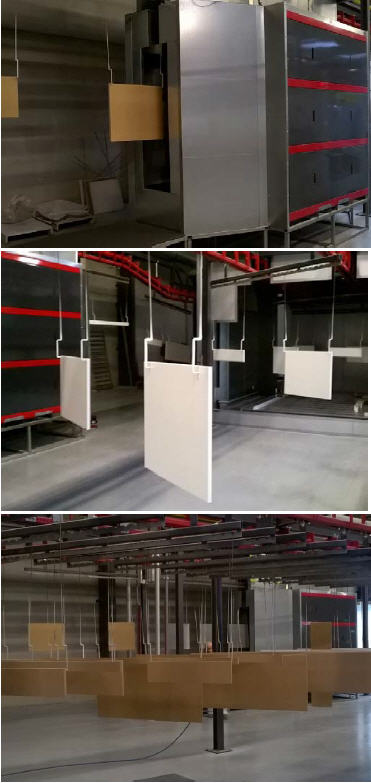

New flexible gascatalytic IR oven for kitchen front panels Copyright Kempa nv Belgien 2016

There is a wide range of surface finish requirements for cooker fronts in terms of design and surface properties. As well as the variety of colours and shapes other properties such as scratch-resistance, chemical resistance and water resistance also play an important part.

Modern powder coatings are of great assistance here. The powder coating must not only run easily but also cure easily.

A versatile, tailor-made gas catalytic infra-red oven from Heraeus ensures a brilliant surface finish, especially for medium density fibre boards (MDF) Cooker fronts made of MDF board are enhanced by a coating. This can be a liquid or powder system, which allow both a seamless coating, with exceptional mechanical and chemical properties.

Kempa Fits the New Heraeus Infrared Oven

The Belgian company Kempa Products supplies kitchen fronts exactly to customer specifications in batches from one upwards. Consequently, in order to meet the powder coating requirements, the drying and curing oven must be flexible enough to meet all situations.

Kempa has used a gas catalytic oven from Heraeus for this essential, flexible heating process since the beginning of the year.

Paul Maeyninckx, managing director of Kempa Products, is delighted and comments, “In partnership with Heraeus, we could determine the plant design and set up the plant so that we can now react flexibly to every customer specification. As a result, we can achieve a very good finish much faster than before”.

Infrared Heating for Powder Coating

Heraeus has supplied Kempa gas catalytic infrared heating systems for two different places – for the pre-heating and for the curing itself. Powder coating on MDF boards is significantly more homogenous if the boards are pre-heated before the actual powder coating. This increases electrical conductivity, which then helps the powder to be distributed more homogenously.

The second gas catalytic infrared oven at Kempa serve to gel and cure the powder coating. Generally, powder absorbs infrared radiation very well, so that the powder itself heats up very quickly and is gelled in significantly shorter time than in a conventional convection oven. As there is no circulation of air, dust inclusion in the coating is eliminated and the powder is not swirled or moved around. A fast melt improves the coating quality and increases the production line speed.

Infrared heat is transferred faster and at higher power than warm air, so that in most cases the oven is shorter than a warm air oven or the production line speed is faster.

The oven at Kempa is 12m long, with a line speed of around two metres per minute. The implemented zone control allows adjustment of every temperature profile according to the requirements of MDF board dimensions or powder type used. Heraeus application specialists worked with Kempa in a series of tests to establish the required oven settings.

Various temperature profiles were investigated to meet the various board sizes and thicknesses and the various coating systems and to establish the fine adjustment of the control required. Finally, various programs to meet the different requirements were incorporated in the control system and these can be called up on demand.

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned company formed in 1851. With expertise, a focus on innovations, operational excellence and an entrepreneurial leadership, we strive to continuously improve our business performance. We create high-quality solutions for our clients and strengthen their competitiveness in the long term by combining material expertise with technological know-how.

Our ideas are focused on themes such as the environment, energy, health, mobility and industrial applications. Our portfolio ranges from components to coordinated material systems which are used in a wide variety of industries, including the steel, electronics, chemical, automotive and telecommunications industries. In the 2015 financial year, Heraeus generated revenues without precious metals of €1.9 bn and a total revenue including precious metal of €12.9 bn . With approximately 12,500 employees worldwide in more than 100 subsidiaries in 38 countries, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialty light sources and systems. In 2015, Heraeus Noblelight had an annual turnover of 158.3 Million € and employed 828 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters, systems and solutions for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

For further information, please contact:

Technical: Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press: Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Abteilung Marketing/Werbung

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…