Controlled laser drilling of microvias

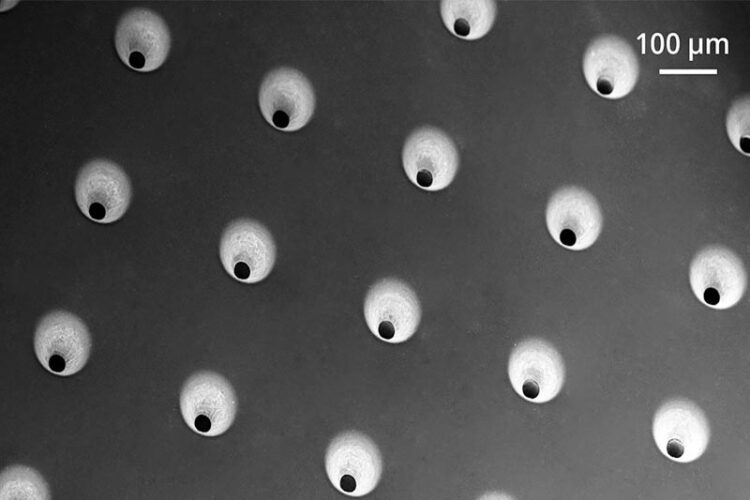

Micrometre-thin vias in printed circuit boards have to be drilled very precisely. A new measuring method should make it possible to control the laser drilling process of microvias in the future.

© 3D-Micromac AG

In the production of printed circuit boards (PCBs), micrometer-diameter vias – known as microvias – are drilled through multilayer PCBs. Lasers can drill through these structures with high throughput and micrometer precision. A measurement technique based on laser-induced breakdown spectroscopy (LIBS) is set to check the quality of the holes inline and control the process.

Because of the high density of circuits and components, modern printed circuit boards are extremely challenging to manufacture. Lasers are used to drill the interconnects between the layers, or microvias, that are less than 200 micrometers in diameter. The drilling process must be fast, cost-effective, flexible and – most importantly – precise, because once the holes have been metalized, they form the electrical contact between the metal layers of the PCB. To ensure good contacting, the insulation material must be completely removed during the drilling process; this will determine the functionality and longevity of the electronic component. Currently, microvias quality control is usually a downstream step, which sometimes uses destructive methods such as cross-sectioning or electrical functional tests. What’s more, they are often just spot checks, which is not enough for safety-critical applications.

Process control of laser parameters for wider use of ultrashort pulse lasers

In the HILaM research project, Fraunhofer IPM, Chemnitz-based laser micromachining specialist 3D-Micromac AG, and ANDUS ELECTRONIC GmbH from Berlin are developing an optical method for the inline quality control of microvias using ultrashort pulse (USP) lasers and the automatic control of the drilling process. The use of USP lasers to structure printed circuit boards has been on the rise because of their ability to produce holes with very small diameters in demanding materials and little space between the vias. USP lasers, however, are not selective in terms of material. This means that, with varying thickness and homogeneity of insulation layers, the drilling process requires precise control.

The researchers employ laser-induced breakdown spectroscopy (LIBS) to analyze and control the ablation process – pulse-resolved, selectively and spatially resolved within each hole. The LIBS sensor is integrated into the system coaxially to the laser and absorbs the plasma emissions of each material that are generated during ablation. The spectrum can be used to determine which material has been removed. If copper is present in the plasma spectrum, this means that the insulation layer has been sufficiently removed from the spot in question. The control algorithm then decides to move the laser to the next position within the hole. This ensures 100 percent inline quality control.

Further Information

The HILaM project (“Hochdynamische Inline-Regelung des Laserbohrens von Microvias” – “Highly Dynamic Inline Control of Laser Drilling of Microvias”) is funded by the German Federal Ministry of Education and Research (BMBF) as part of the program “Photonics for the digitally integrated world – fast optical controls of dynamic processes”. Project partners are the Fraunhofer Institute for Physical Measurement Techniques IPM, 3D-Micromac AG (project coordination) and ANDUS ELECTRONIC GmbH.

Wissenschaftliche Ansprechpartner:

Dr. Carl Basler, Project Manager Optical Surface Analytics, >carl.basler@ipm.fraunhofer.de<

Weitere Informationen:

http://www.ipm.fraunhofer.de/en Fraunhofer Institute for Physical Measurement Techniques IPM

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Faster, more energy-efficient way to manufacture an industrially important chemical

Zirconium combined with silicon nitride enhances the conversion of propane — present in natural gas — needed to create in-demand plastic, polypropylene. Polypropylene is a common type of plastic found…

Energy planning in Ghana as a role model for the world

Improving the resilience of energy systems in the Global South. What criteria should we use to better plan for resilient energy systems? How do socio-economic, technical and climate change related…

Artificial blood vessels could improve heart bypass outcomes

Artificial blood vessels could improve heart bypass outcomes. 3D-printed blood vessels, which closely mimic the properties of human veins, could transform the treatment of cardiovascular diseases. Strong, flexible, gel-like tubes…