The laser – tool for innovations: LZH at the Hannover Messe 2016

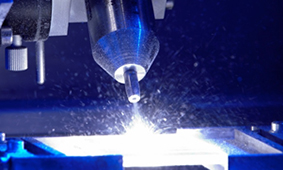

The laser – tool for innovations. Photo: LZH

Based on current research projects the LZH will show: The advantages of magnesium as manufacturing material, how the laser can make underwater works safer and more efficient, how CFRP will change the production of tomorrow and how parts become smart through functionalized surfaces and integrated sensors.

Additive Manufacturing

With Selective Laser Melting (SLM), the limits of conventional manufacturing processes can be overcome. In that way, it allows for manufacturing smallest structures, complex parts or individual implants “out of nothing”. The LZH develops processes for the additive manufacturing of load-adapted parts and for the processing of special materials, such as magnesium. This material has a high specific strength, is easy to recycle and virtually available in unlimited amounts.

Efficient processes

Underwater works are often time-consuming and physically very demanding for the divers. With conventional methods for underwater separating, light arc oxygen cutting is mainly used. The electrodes are hand-guided. The LZH develops an automated laser-based cutting process for sheet pilings that makes it possible to achieve a significant increase in cutting speed. With this process, underwater metal processing will become much faster and more cost-efficient. Moreover, the work for the divers becomes safer and more efficient.

Innovative lightweight construction

The three-dimensional, automated processing of thermoplastic, fiber reinforced materials, such as carbon fiber reinforced plastics (CFRP) is a precondition for this lightweight material to find its way into series production. The laser penetration welding process developed by the LZH enables the safe joining of these materials. The institute will present the current state of research in the fields of cutting, drilling and ablation.

Smart parts

Functionalized surfaces and integrated sensors impart new or improved properties to parts, and increase their efficiency and durability. The LZH works on the micro-structuring of metals and non-metals for mechanical engineering, medical technology and the solar industry. With integrated sensors, even smallest strains in those parts of a machine tool that are difficult to deform can be measured. Thus, for example the condition of the machine or the process forces and vibrations can be measured during operation, and this information can be used to control and optimize the process.

Visit the LZH at the Lower Saxony Pavilion in hall 2, stand A08!

Media Contact

More Information:

http://www.lzh.de/All latest news from the category: Trade Fair News

Newest articles

Faster, more energy-efficient way to manufacture an industrially important chemical

Zirconium combined with silicon nitride enhances the conversion of propane — present in natural gas — needed to create in-demand plastic, polypropylene. Polypropylene is a common type of plastic found…

Energy planning in Ghana as a role model for the world

Improving the resilience of energy systems in the Global South. What criteria should we use to better plan for resilient energy systems? How do socio-economic, technical and climate change related…

Artificial blood vessels could improve heart bypass outcomes

Artificial blood vessels could improve heart bypass outcomes. 3D-printed blood vessels, which closely mimic the properties of human veins, could transform the treatment of cardiovascular diseases. Strong, flexible, gel-like tubes…