Metal printing offers low-cost way to make flexible, stretchable electronics

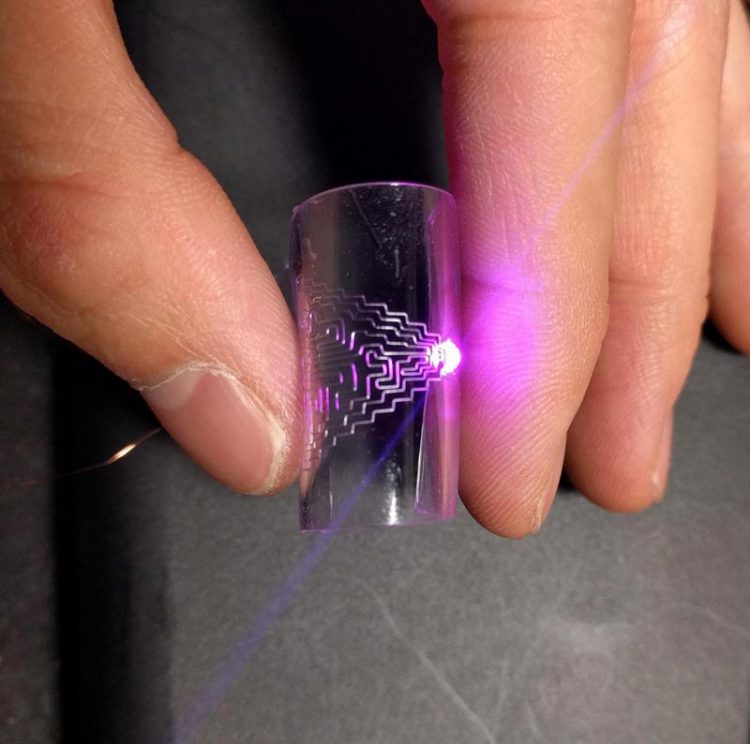

This prototype demonstrates the potential of a new technique for printing flexible, stretchable circuits. Credit: Jingyan Dong, North Carolina State University

“Flexible electronics hold promise for use in many fields, but there are significant manufacturing costs involved – which poses a challenge in making them practical for commercial use,” says Jingyan Dong, corresponding author of a paper on the work and an associate professor in NC State's Edward P. Fitts Department of Industrial & Systems Engineering.

“Our approach should reduce cost and offer an efficient means of producing circuits with high resolution, making them viable for integrating into commercial devices,” Dong says.

The technique uses existing electrohydrodynamic printing technology, which is already used in many manufacturing processes that use functional inks. But instead of ink, Dong's team uses molten metal alloys with melting points as low as 60 degrees Celsius. The researchers have demonstrated their technique using three different alloys, printing on four different substrates: one glass, one paper and two stretchable polymers.

“This is direct printing,” Dong says. “There is no mask, no etching and no molds, making the process much more straightforward.”

The researchers tested the resilience of the circuits on a polymer substrate and found that the circuit's conductivity was unaffected even after being bent 1,000 times. The circuits were still electrically stable even when stretched to 70 percent of tensile strain.

The researchers also found that the circuits are capable of “healing” themselves if they are broken by being bent or stretched too far.

“Because of the low melting point, you can simply heat the affected area up to around 70 degrees Celsius and the metal flows back together, repairing the relevant damage,” Dong says.

The researchers demonstrated the functionality of the printing technique by creating a high-density touch sensor, fitting a 400-pixel array into one square centimeter.

“We've demonstrated the resilience and functionality of our approach, and we're open to working with the industry sector to implement the technique in manufacturing wearable sensors or other electronic devices,” Dong says.

###

The paper, “Electrohydrodynamic (EHD) Printing of Molten Metal Ink for Flexible and Stretchable Conductor with Self-Healing Capability,” is published in the journal Advanced Materials Technologies. Lead author of the paper is Yiwei Han, a Ph.D. student at NC State. The work was done with support from the National Science Foundation under grant numbers CMMI-1333775 and CBET-1344618.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…