Smart plaster could accelerate the healing of chronic wounds

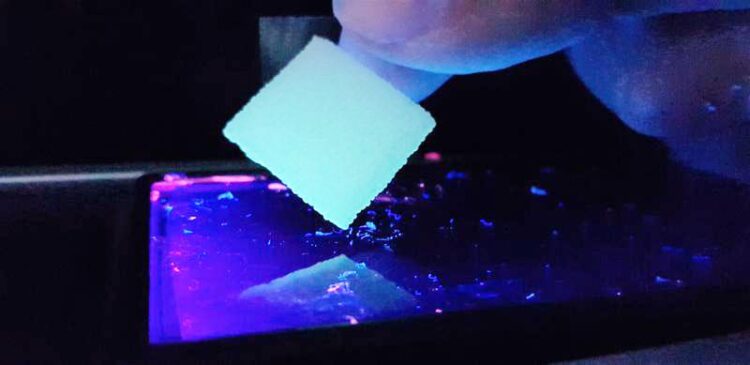

The patch can be custom made in a 3D printer and is activated by green light.

Photo: Leonard Siebert

International cooperation between materials science and medicine develops gel patches from a 3D printer that can be activated individually.

Circulatory disorders, diabetes or lying in the same position for extended periods can all lead to chronic wounds that do not heal. There are hardly any effective treatment options. A materials science research team from Kiel University (CAU), together with colleagues from the University Medical Center Schleswig-Holstein (UKSH), Harvard Medical School, USA, and Dankook University in South Korea, has developed a wound patch with enhanced healing functions which can be individually adapted for each patient. The 3D-printed patch has antibacterial properties, supplies the wound with oxygen and moisture, and supports the formation of new tissue. The properties are activated and controlled by irradiation. The scientists from materials science and medicine recently presented their concept in the scientific journal Advanced Functional Materials, where it featured as the cover story.

The basis of the newly developed patch is a medical hydrogel. Due to its high water content of 90 percent and comparatively large spacing on the microscale, the patch can provide optimal care for chronic dry wounds. However, the most important component is antibacterial zinc oxide microparticles, which react to light and were developed by the materials science researchers in Kiel. Together with a team from the Brigham and Women’s Hospital of Harvard Medical School, Boston, they found a way to apply special proteins to the microparticles. These proteins are activated with cell-friendly green light, and thereby stimulate the formation of new blood vessels. The improved blood circulation gives rise to new tissue, which enables the wound to close.

In the long term, clinics should be able to produce individual patches themselves using a 3D printer

By irradiation with light the healing effect of the patch can be optimally adapted to the course of treatment of the individual patients. The antibacterial zinc oxide tetrapods, which react to light, are integrated into the patch during 3D printing.

Image: Leonard Siebert

“By controlling the effects of the patch with light, we can adapt the course and dosage of the treatment to the individual needs of patients,” said Rainer Adelung, Professor of Functional Nanomaterials at the Institute for Materials Science at Kiel University and spokesperson for the Research Training Group “Materials for Brain”. Materials science refers to this as a ‘smart’ material, that independently reacts to external stimuli and can be controlled by them. Similarly functioning hydrogel patches already exist, which can also be activated in a targeted manner – but their therapeutic effects are triggered through heat or electrical signals. “However, these concepts have the disadvantage that the wound also warms up and the hydrogels begin to disintegrate,” explained Adelung.

The research team hopes that in the long term, clinics can produce its multifunctional, controllable patches themselves using a 3D printer, and activate the patches directly on patients with very bright, green LEDs. “The shape of the patch as well as the concentration of the zinc oxide particles and the type of protein can be individually adjusted by 3D printing,” said first author Dr. Leonard Siebert, who just completed his PhD on innovative 3D-printing methods at Kiel University. During a research stay of several months at the renowned Harvard Medical School in Boston, the materials scientist researched in the working group of Professor Su Ryon Shin, who produces medical hydrogels using special biological 3D printers. “Our particles have a tetrapodal shape, i.e. they consist of several ‘arms’. This means that many of our important proteins can be applied to them, but they do not fit through conventional print nozzles,” said Siebert to describe one of the challenges of their approach. In Boston, he finally developed a method to print the zinc oxide particles from his Kiel working group together with the hydrogels.

Test results from Kiel, the USA and South Korea show potential of the patch for personalised medicine

In addition, the Kiel materials scientists worked closely with Professor Helmut Fickenscher, a specialist in infection medicine at the CAU and the University Medical Center Schleswig-Holstein (UKSH). He and his team tested the antibacterial properties of the patch: they put it on a bacterial biofilm for 72 hours and discovered that the bacteria do not proliferate within a radius of several millimetres around the patch. “For this test, we used two typical wound germs with two entirely different structures: Staphylococcus aureus and Pseudomonas aeruginosa. The patch demonstrated a therapeutic effect for both fundamental types, which suggests a universal effect,” summarised Dr Gregor Maschkowitz, medical microbiologist at the UKSH. Further in vivo tests were conducted at the NBM Global Research Center for Regenerative Medicine at Dankook University, South Korea. The initial results there also indicate good tolerability of the patch and improved wound healing.

“This patch is an exciting concept for personalised medicine, to treat people using customised treatments as precisely, effectively and gently as possible. It is a tangible example of the promising potential of collaboration between medicine and materials science, which will become increasingly important in the future,” said Professor Fickenscher about the interdisciplinary cooperation project. Now that the initial tests have shown that their concept works well in principle, the researchers want to improve the control using light even further, so that patients can be offered even more effective personalised wound treatment in future.

Photos are available to download:

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-1.jpg

Caption: The patch can be custom made in a 3D printer and is activated by green light. © Leonard Siebert

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-2.jpg

Caption: Jointly researching the healing of chronic wounds (from left to right): Rainer Adelung, Professor of Functional Nanomaterials at the CAU, Helmut Fickenscher, Professor of Infection Medicine at the CAU and the UKSH and Su Ryon Shin, Assistant Professor at the Brigham and Women’s Hospital of Harvard Medical School, Boston, USA.

© Julia Siekmann, CAU / private

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-5.jpg

Caption: In tests, the hydrogel patch demonstrated its antibacterial efficacy against two typical wound germs: with Pseudomonas aeruginosa (right), significantly fewer bacteria have colonised the area directly around the patch after 72 hours (dotted circle). With Staphylococcus aureus (left), the bacteria have even disappeared completely from the area directly around the patch (dark grey circle).

© Gregor Maschkowitz

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-3.jpg

Caption: During his PhD Dr Leonard Siebert investigated how to print the special hydrogels for the smart patch at Harvard Medical School.

© Julia Siekmann, CAU

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-4.jpg

Caption: Dr Gregor Maschkowitz, a medical microbiologist in the working group of Professor Helmut Fickenscher at the UKSH, demonstrated the antibacterial efficacy of the patch against typical wound germs.

© Julia Siekmann, CAU

https://www.uni-kiel.de/de/pressemitteilungen/2021/184-Pflaster-6.jpg

Caption: The healing effect of the patch can be influenced by irradiation with light, and thereby optimally adapted to the course of treatment of the individual patients. The antibacterial zinc oxide tetrapods, which react to light, are integrated into the patch during 3D printing.

© Leonard Siebert

Wissenschaftliche Ansprechpartner:

Prof. Dr rer. nat. Rainer Adelung

Spokesperson for the Research Training Group 2154 “Materials for Brain”

Functional Nanomaterials working group,

Institute for Materials Science

Tel.: 0431/880-6116

E-mail: ra@tf.uni-kiel.de

http://www.grk2154.uni-kiel.de/en

http://www.tf.uni-kiel.de/matwis/fnano/de

Dr-Ing. Leonard Siebert

Functional Nanomaterials working group

Tel. 0431/ 880-6181

E-mail: lesi@tf.uni-kiel.de

Prof. Dr med. Helmut Fickenscher

The Institute of Infection Medicine

Tel.: +49 431 500-15300

E-mail: fickenscher@infmed.uni-kiel.de

http://www.uni-kiel.de/infmed

Originalpublikation:

Original publication:

Leonard Siebert, Eder Luna-Cerón, Luis Enrique García-Rivera, Junsung Oh, JunHwee Jang, Diego A. Rosas-Gómez, Mitzi D. Pérez-Gómez, Gregor Maschkowitz, Helmut Fickenscher, Daniela Oceguera-Cuevas, Carmen G. Holguín-León, Batzaya Byambaa, Mohammad A. Hussain, Eduardo Enciso-Martínez, Minsung Cho, Yuhan Lee, Nebras Sobahi, Anwarul Hasan, Dennis P. Orgill, Yogendra Kumar Mishra, Rainer Adelung, Eunjung Lee, Su Ryon Shin. Light-Controlled Growth Factors Release on Tetrapodal ZnO-Incorporated 3D-Printed Hydrogels for Developing Smart Wound Scaffold, Adv. Funct. Mater., Volume 31, Issue 22, May 26, 2021, 2007555, https://doi.org/10.1002/adfm.202007555

Weitere Informationen:

https://www.uni-kiel.de/en/research/details/news/184-pflaster link to the press release

http://www.kinsis.uni-kiel.de/en Website KiNSIS – the priority research area Kiel Nano, Surface and Interface Science at Kiel University. This interdisciplinary cooperation trying to understand structures and processes in the nano dimensions could lead to the development of novel sensors and materials, quantum computers, advanced medical therapies and much more.

Media Contact

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…