Photovoltaics: easy implementation thanks to modern printing techniques

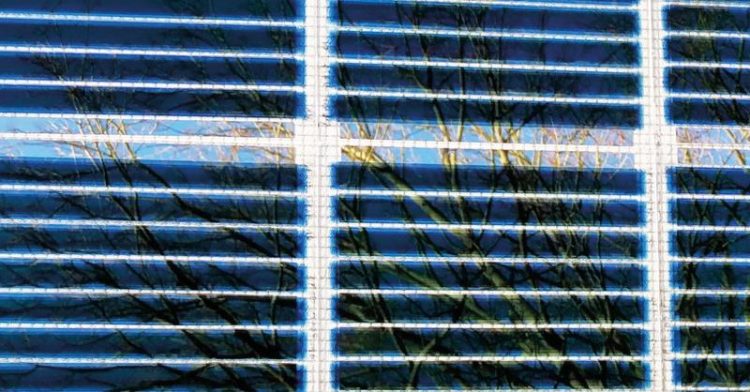

The printed stripes make all the difference. By series connection, each square of ten stripes is capable of producing a voltage of about 8 Volt. Fraunhofer IAP

Renewable energy has become an important topic in today’s society. Modern printing solutions promise the easy and cost efficient production of photovoltaics elements, even beyond architectural uses.

At LOPEC 2018 Fraunhofer IAP displays its competences, especially regarding inkjet-printing techniques. With these solutions, façade elements for the production of solar energy can be printed. Due to the printing technology used, these elements can be produced on a larger scale with reduced costs compared to conventional production methods.

Further applications can be found in optoelectronics and medicine. The process of printing is also applicable within the textile industry. Alongside a façade element the researchers display a jacket with photovoltaic elements which produces enough energy to charge a mobile phone and operate hand warming pads. The jacket even stores the energy. Currently the IAP-researchers are developing a solar powered LED-bicycle jacket together with industry partners.

The institute has its own pilot plant for printed electronics on which the displayed elements were produced. “On our pilot plant we develop printing solutions in a very industry-oriented way. Together with our clients we then implement these solutions into their large scale plants based on the expertise we gather through our pilot plant. We improve our printing methods constantly and individually adapt them to our customers’ needs”, Dr. Armin Wedel, head of the research division Functional Polymer Systems at the Fraunhofer IAP, explains.

For small scale surfaces the scientists are working on implementing a novel drop-on demand system: esjet-printing (electro static printing). This technology allows the use of a wider range of inks, especially essential for printing very fine structures. Widening the range of possible inks regarding their viscosity is a big step. Inkjet-printing sets limits to the used ink’s viscosity. With esjet-printing, fine metal grids with high transmission rates can be printed and thus replace conventional transparent ITO-electrodes in photovoltaics components.

The Fraunhofer IAP and the OLED Technology Alliance, GOTA

Fraunhofer-researchers also present first customer projects resulting from the GOTA alliance. The Fraunhofer IAP develops processes and materials for future OLED production facilities in close cooperation with the plant engineering companies MBraun Inertgas-Systeme GmbH in Munich, Notion GmbH in Schwetzingen and ARDENNE GmbH in Dresden. The four partners have formed the OLED Technology Alliance GOTA in order to offer the market turnkey OLED production facilities.

The Fraunhofer IAP has been conducting research on organic electronic systems for over 25 years and focuses on solution-processed devices used in OLEDs, QLEDs, OTFT, OPV, perovskite solar cells, sensors and actuators. Several processing technologies are available in a large clean room. These include spin coating, material evaluation in lab devices, advanced processing technologies, such as inkjet printing and high-precision slot die coating on a robot-controlled S2S pilot line for dimensions up to 150 mm x 150 mm, and various evaporation and encapsulation technologies.

Media Contact

More Information:

http://www.iap.fraunhofer.deAll latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…