New Sinumerik features improve productivity and precision

- Drive optimization called automatically by the part program boosts productivity

- Automatically switching the dynamic values to rapid traverse and interpolation steps, improves both quality and speed

- New compensations increase machine precision and reduce speed-dependent friction effects

Siemens offers new features for increasing machine precision with its software version 4.7 for Sinumerik Operate. User benefit: The new software-supported features increase machining precision while also improving machine productivity.

For example, the Sinumerik Auto Servo Tuning algorithm makes it possible to optimize machine dynamics so that control loop parameters and damping filters can be automatically calculated and adjusted for drive optimization.

Where flexible production leads to changes in the mass of workpieces, tool holders or tools on a machine, the parameters for increasing productivity and quality can be adjusted via Auto Servo Tuning. With the latest software version 4.7 for Sinumerik Operate the algorithm can be activated directly via the CNC program on the Sinumerik 840D sl. As a result, each time the processing parameters change, an optimization occurs between processing steps, leading to superior precision and maximum productivity.

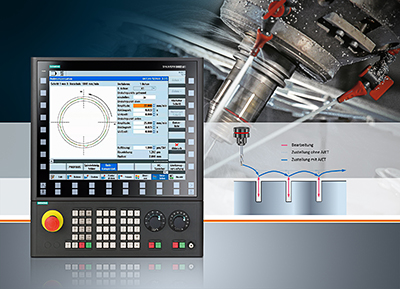

The Adapt Jerk Filter Time (AJET) feature for the Sinumerik 840D sl starts by optimizing motion sequences. Producing a workpiece typically involves a sequence of interpolation and fast traverse. This is clearly evident in drilling patterns, for example.

AJET recognizes these different phases and switches between the parameters for precision and maximum acceleration. By automatically switching between operating parameters, a machine achieves the best possible quality during the machining phase and superior productivity during the positioning phase.

The latest software version 4.7 for the Sinumerik Operate also includes machine optimizations, such as improved friction compensation. Friction between materials occurs in every machine tool and has a negative effect on contour accuracy.

Today every Sinumerik includes friction compensation for just this reason, thereby proactively compensating for contouring errors due to static or sliding friction. With the latest software version 4.7, Sinumerik 840D sl and Sinumerik 828D also offer new speed-dependent compensation for friction, better eliminating friction-dependent path deviations. This ensures consistently high contour accuracy and workpiece precision. Guided masks perfectly support initial operation.

Further information about Sinumerik is available at www.siemens.com/sinumerik

Further information about Siemens at the EMO 2015 is available at www.siemens.com/emo

Additional press releases about Siemens innovations at the EMO 2015 are available at www.siemens.com/press/emo2015

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015100004DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…