Joining gun bonds metal and plastic within seconds

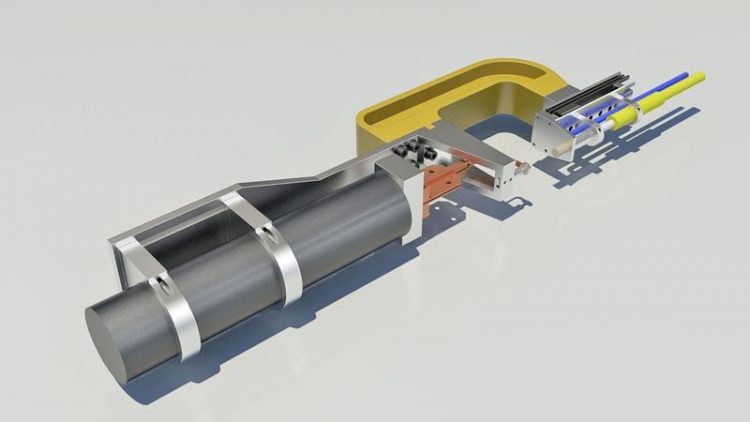

The joining gun bonds metal and plastic in seconds. © Fraunhofer IWS

The HeatPressCool-Integrative process HPCI

The connection of plastics and metals poses a challenge, due to the different physical properties of the two materials.

All conventional joining options, such as bonds using adhesives or rivets have their disadvantages: adhesives need time to harden, which delays further processing.

Plastics can be easily damaged during riveting. Furthermore, both adhesive bonding and riveting require additional materials which increases production costs.

The HeatPressCool-Integrative process, developed at the Fraunhofer IWS Dresden, is integrated into the joining gun enabling the direct and precise bonding between metal and plastic components in a matter of seconds.

During this process, the two materials are pressed together and the metal at the bonding point is subjected to targeted inductive heat. This causes the thermoplastic material to partially melt, which in turn directly forms a firm bond with the metal as the plastic solidifies.

More stable connection by pre-treatment of the metal

The Fraunhofer IWS researchers pretreat the metal with lasers to optimize the adhesion between metal and plastic to create anchoring structures.

“The special feature of this process is that we use laser ablation to drill relatively deeply into the metal, to a depth of up to a hundred micrometers, where the plastic can penetrate and then cool down, contract and form a secure fit in this structure. This generates a highly stable bond”, says Annett Klotzbach.

Easy application in proven system technology

In order to integrate the joining gun into the existing system technology in manufacturing operations, it provides a modular structure. It can, for example, be mounted on a robot arm in place of a spot welding gun.

The joining gun can be applied wherever metal and plastics need to be precisely bonded, for instance in vehicle body construction in the automotive industry or for stainless steel panels in refrigerators or dishwashers.

https://www.fraunhofer.de/en/press/research-news/2019/january/joining-gun-bonds-…

Media Contact

All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…