Innovative Infrared System Dries and Sinters Printed Electronics Almost 2000 Times Faster than Previously

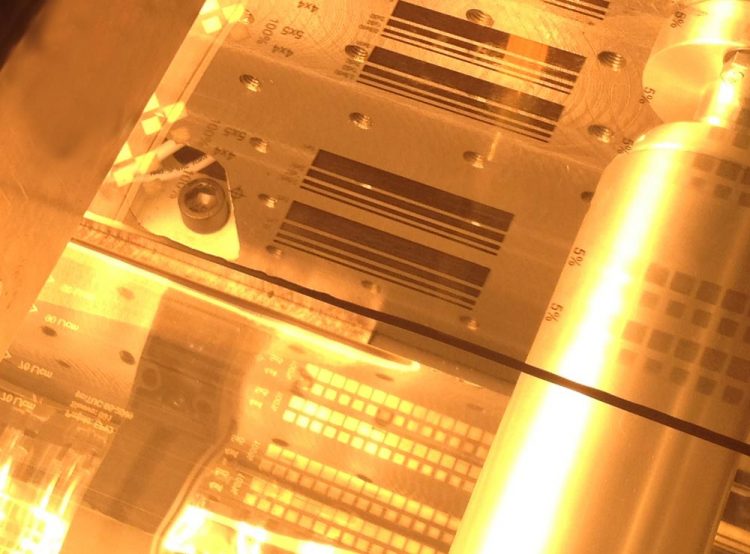

Infrared emitters dry and sinter within 0.32 seconds. Copyright Heraeus Noblelight 2016

The continuous printing of electronics for displays or solar cells, depends on a rapid drying of the surface and good conductivity of the silver inks. A newly developed infrared module from Heraeus Noblelight achieves this in significantly less than one second (0.32 secs) and is consequently almost 2000 times faster than conventional drying techniques.

Heraeus developed and installed the made-to-measure module in a roll-to-roll printing system. In tests, the infrared radiation proved far superior to drying and sintering using conventional hot plates or hot air ovens. These trials were carried out in the Department of Digital Printing and Graphics Technology of Chemnitz Technical University and the Fraunhofer Institute for Electronic Nanosystems.

Heraeus will be presenting this exciting innovation, together with other UV, Infrared, and Flashlamp systems for the printed electronics sector at the Lopec exhibition in Munich in April 2016.

Metallic nano particles for printed electronics are often deposited onto flexible and polymeric materials using Inkjet printing and are then dried and sintered. On a laboratory scale, this is mostly achieved using hot plates or hot air. However, for mass production, the Roll-to-Roll (R2R) technique must be used. And this means that drying and sintering must be significantly faster.

New techniques have been investigated, such as microwaves, lasers, Intense Pulse Light (IPL) and infrared radiation. The optimum technique must be able to dry and sinter quickly and efficiently, while at the same time causing no damage to the polymer substrate, which is often temperature sensitive.

Heraeus has developed a purpose-built infrared module for an R2R printing system. This has been used to carry out tests on the infrared drying and sintering of inkjet printed silver coatings on polyethylene naphtalate. (PEN). It could be shown that the post treatment of the freshly printed deposit led to a conductivity of up to 15% of pure silver.

Compared with drying and sintering with conventional hot plates or hot air, infrared radiation achieved twice the conductivity in only 0.32 seconds. In contrast, using a hot plate, drying and sintering took about ten minutes.

Using electron microscope imaging, the microstructure of the sintered silver particles was then analyzed in relation to the IR parameters (filament temperature of the emitter, duration and power of the radiation and distance of the emitter and reflector from the substrate.)

After optimizing these parameters, the silver was then dried at 50 kW/m2 and sintered at 150 kW/m2. Using the same short wave emitter each time, merely requiring control adjustment. The printed electronics on the continuous foil can therefore be dried and sintered in one stage, at high belt speeds of up to 1 m/sec and an irradiation time of less than 0.32 seconds.

This research and development work was recently published in the Journal Materials Chemistry C: E. Sowade, H. Kang, K.Y. Mitra, O.J. Weiß, J. Weber, R.R. Baumann, Roll-to-roll infrared (IR) drying and sintering of an inkjet-printed silver nanoparticle ink within 1 second, J. Mater. Chem. C. 3 (2015) 11815–11826. doi:10.1039/C5TC02291F.

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned company formed in 1851. With expertise, a focus on innovations, operational excellence and an entrepreneurial leadership, we strive to continuously improve our business performance.

We create high-quality solutions for our clients and strengthen their competitiveness in the long term by combining material expertise with technological know-how. Our ideas are focused on themes such as the environment, energy, health, mobility and industrial applications. Our portfolio ranges from components to coordinated material systems which are used in a wide variety of industries, including the steel, electronics, chemical, automotive and telecommunications industries.

In the 2014 financial year, Heraeus generated product revenues of €3.4 bn and precious metal revenues of €12.2bn euros. With around 12,600 employees worldwide in more than 100 subsidiaries in 38 countries, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources and systems. In 2014, Heraeus Noblelight had an annual turnover of 137.3 Million € and employed 884 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters, systems and solutions for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

For further information, please contact:

Technical: Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press: Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Abteilung Marketing/Werbung

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com

Media Contact

All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…