Quick and safe laser joining of steel-aluminum mixed connections

Quick and safe joining of steel and aluminum using remote laser welding Photo: LZH

Robust and lightweight steel-aluminum composite components are ideal for reducing vehicle weight and can help reducing pollutant emissions. In order to optimize the joining of mixed compounds for series production in the automotive industry, the scientists at the LZH have developed processes for joining two- and three-sheet metal joints with high welding speeds of up to seven meters per minute.

The basis for the remote laser beam welding process is a 3D scanner optic, newly developed by the TRUMPF Laser GmbH. With this, complex three-dimensional seam geometries are possible even with large structures. Thus, the process is particularly interesting for car body construction and can replace complex robot movements.

Stable joint in the event of a crash

The weld joint achieves a shear tensile strength of approximately 67 percent of the aluminum alloy. Due to the parallel arrangement of three welds, this can even be increased to about 95 percent. The process was developed for battery cases of electric cars, seat structures and car body parts. The Volkswagen AG (VW) has quasi-statically and dynamically tested the validation components for car body applications. The joined mixed compounds have an advantageous crash behavior, since the joining partners remain safely connected.

Use of the laser minimizes intermetallic phases

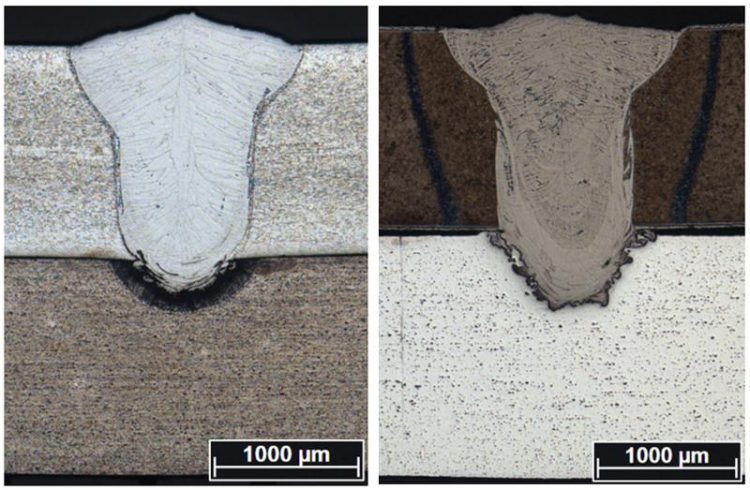

One of the challenges in welding steel and aluminum is to avoid hard and brittle intermetallic phases in the welding seam, which cannot be completely avoided. During laser welding, a low amount of heat is introduced into the workpiece in a well targeted manner. Therefore, these phases are formed to a reduced extent and the dissimilar materials are melted as defined. Thus, it is possible to control the mixing of the joint.

About LaserLeichter

In the joint project “Development of Laser-Based Joining Technologies for Similar Lightweight Constructions” (LaserLeichter) the partners LZH, VW, inpro Innovationsgesellschaft für fortgeschrittene Produktionssysteme in der Fahrzeugindustrie mbH, Precitec GmbH & Co. KG, MATFEM Partnerschaft Dr. Gese & Oberhofer, LUNOVU GmbH, Scherdel Marienberg GmbH, InfraTec GmbH, Brandenburgische Technische Universität Cottbus-Senftenberg and the Fraunhofer-Institut für Werkstoff- und Strahltechnik IWS worked together under the coordination of the Robert Bosch GmbH.

Associated partners were TRUMPF Laser GmbH, ASTOR Schneidwerkzeuge GmbH, ThyssenKrupp Steel Europe AG, Bond-Laminates GmbH and Hydro Extrusion Offenburg GmbH (formerly SAPA Aluminium Profile GmbH). LaserLeichter was funded by the Federal Ministry of Education and Research (BMBF) within the scope of the funding initiative “Photonic Processes and Tools for Resource-Efficient Lightweight Construction“.The consortium was coordinated by the LZH.

https://www.lzh.de/en/publications/pressreleases/2018/quick-and-safe-laser-joini… Press release with video

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…