Porous silicon layers for more efficient lithium-ion batteries

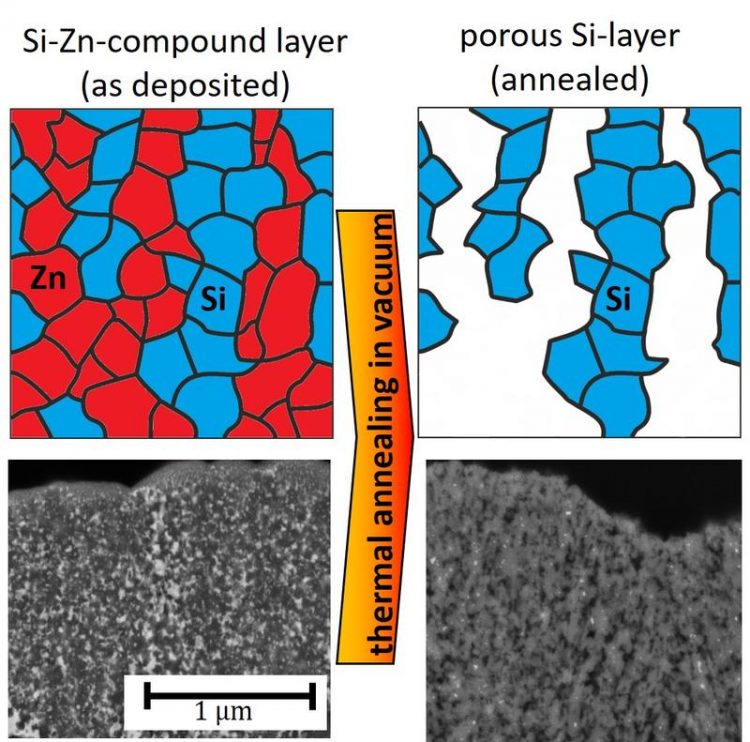

Scheme of the formation of separated grains of zinc (red) and silicon (blue) after deposition (left) and porous silicon film after expelling zinc by thermal annealing (right). © Fraunhofer FEP; Picture in printable resolution: www.fep.fraunhofer.de/press

Lithium-ion batteries are well established due to their good properties. They have a higher energy density than other batteries. Therefore, they are used in cameras, watches, mobile devices and especially for electric vehicles. However, from a technical point of view they still offer a high potential for improving and optimizing of battery cells.

Lithium-ion batteries consist of an arrangement of different layers, each with different functions. The cathode and anode are the two electrodes of the battery, which are connected electrically via conductive electrolyte inside the cell.

Currently, there are many research activities worldwide for developing new materials and alternative manufacturing processes in order to improve the battery performance, especially for mobile devices and electromobility.

Important aspects for prospective technologies are resource conservation, environmental protection and safety. In addition, batteries should be produced sustainably and cost-effectively with large throughputs.

Within the project PoSiBat a cost-efficient and environmentally friendly process was developed for fabricating porous silicon layers as anode material. The replacement of currently used graphite materials by silicon promises an almost tenfold increase in the specific charging capacity of the anode.

However, the charging and discharging process leads to an enormous change in volume of the silicon and therefore to a rapid mechanical and electrochemical destruction of the material compound and thus to cell failure.

Dr. Stefan Saager from Fraunhofer FEP explains the innovation: “We developed a process in which silicon and zinc are simultaneously deposited on metal substrates. By applying a subsequent heat treatment, the zinc re-evaporates from the layer, and pores are generated at the locations of former zinc grains. The porous structure in the silicon provides adequate space for its expansion during the charging process and thus capacity fade is minimized. The porous structure can be manipulated and optimized to the specific battery requirements by adapting process parameters. The zinc can be collected and reused in the conceived process.”

The porous silicon layers show an encouraging battery performance, which is demonstrated by an initial charging capacity of more than 3,000 mAh/gSi and a comparably good cycle stability.

The expertise of the Fraunhofer FEP lies in the coating of metal substrates and foils with zinc and silicon, which is possible with very high coating rates in conventional non-toxic vacuum processes. These processes enable high throughput and low manufacturing costs. At the Fraunhofer Institute for Material and Beam Technology IWS, the electrochemical properties of the porous coatings were characterized.

The scientists at the Fraunhofer FEP are now looking forward to collaborating with battery manufacturers to transfere the results into high-performance products. They are open for cooperations.

*About the project PoSiBat:

In the PoSiBat research project (project duration: September 1, 2016 to May 31, 2019), fundamental investigations were carried out into the production of highly porous silicon layers and their potential for the production of Lithium-ion batteries with very high energy density. The focus was on replacing conventional materials in the production of negative battery electrodes with silicon, a material with a particularly high capacity for storing lithium ions based on mass or volume. The material development is aimed in particular at applications in vehicles where high energy densities and high currents are required of the battery. The project also developed a concept to scale up the new technologies to a production process. The project has received funding by the European Union and the Free State of Saxony, funding reference: 100275833.

*Fraunhofer FEP during V2019:

Industrial Exhibition:

8. October 2019, 13:00 – 22:00; 9. October 2019, 09:00 – 17:30; 10. October 2019,

09:00 – 13:00

Booth No. 22

Poster:

Untersuchung von Technologien zur Abscheidung von verschleißmindernden

aluminiumreichen TiAlN-Schichten

M. Höhn*, M. Krug*, F. Fietzke**, B. Scheffel**,U. Ratayski***, D. Rafaja***, I. Garrn****,

G. Giersch****

* Fraunhofer IKTS Dresden

** Fraunhofer FEP Dresden

*** TU Bergakademie Freiberg

**** Dr. Gühring KG Chemnitz

Talks:

9. October 2019, 12:00 – 12:30, WS1 – V12

Herstellung von porösen Silizium-Schichten für Anwendungen in der Batterietechnik

Stefan Saager, Fraunhofer FEP

10. October 2019, 09:00 – 09:30, WS3 – V07

Anspruchsvolle laseroptische Beschichtungen durch Inline-Magnetronsputtern

Dr. Peter Frach, Fraunhofer FEP

Workshop:

WS 1: Energie – Dünnschicht-Technologie für Energiesysteme

08. 10. 2019, 11:30 – 18:00

09. 10. 2019, 11:30 – 12:30

Program chairs:

Dr. Torsten Kopte, Fraunhofer FEP, Dresden

Dr. Volker Sittinger, Fraunhofer IST, Braunschweig

Dr. Martin Dimer, VON ARDENNE GmbH

Dr. Grit Hüttl, GfE Fremat GmbH, Freiberg

Tour:

10. October 2019, 13:00 – 16:00

At the end of V2019 the Dresden research locations open their doors. On the Fraunhofer Campus on Dresden's Winterbergstrasse, laboratories and facilities of the Fraunhofer IWS, Fraunhofer IKTS and Fraunhofer FEP will be visited, information about current research projects will be provided and possibilities for joint research projects will be discussed.

Press contact:

Ms. Annett Arnold

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Phone +49 351 2586 333 | presse@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Germany | www.fep.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…