Conference on Laser Polishing – LaP: Fine Tuning for Surfaces

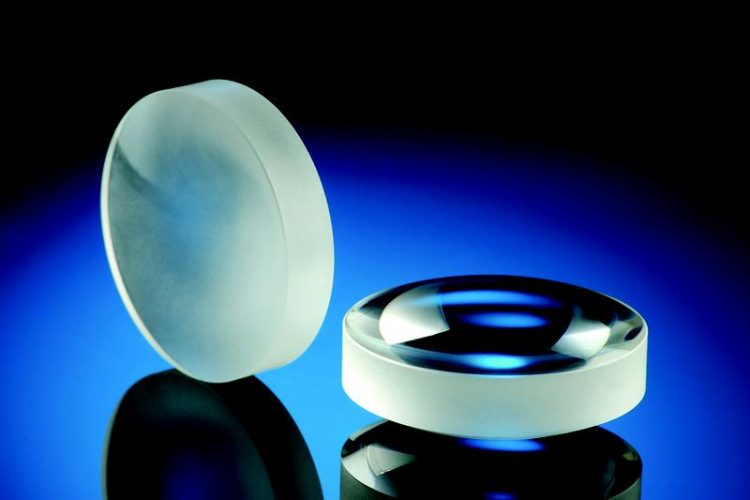

Laser-polished sphere made out of BK7. © Fraunhofer ILT, Aachen, Germany.

Laser polishing is a relatively new process that has only been used for selected fields of applications in the industry: for example, machining metals for toolmaking and automotive engineering, as well as processing glass optics.

International conference

Prior to 2014, the pioneers of this process did not have the opportunity to exchange research results in a wider and international context. That is why Fraunhofer ILT launched the first “Conference on Laser Polishing – LaP” in 2014, which has been held every two years since then and has become the international meeting place for laser polishing experts.

“If you look at the specialist literature, more than 80% of the research groups working on the topic worldwide have attended the LaP conference so far,” states Dr. Edgar Willenborg, Head of the Laser Polishing Group at Fraunhofer ILT.

“Researchers from all over the world – from China, Russia, Canada, many European countries and the USA – have come to the conference. That's why English is the conference language, also at the third LaP”. While the majority of the 20 lectures come from academia, the participants come roughly equally from industry and research.

Focus on technical surface properties

“Researchers are concentrating more and more on the properties of surfaces relevant to specific applications,” says the expert. “In the beginning, it was primarily about lowering the roughness, but now more and more functional tests and application tests are being added”.

For example, users would like to eliminate microdefects to increase the lifetime of a metallic component, or to polish particularly complex optical glass surfaces. One of the new applications, covered for the first time at LaP, is the laser polishing of additively manufactured components made of plastic.

Many speakers have one goal in common: to create a broad, scientific basis for the industrial use of laser polishing. Willenborg: “With hand polishing, it is possible to achieve a lower roughness on metallic components, but it is much slower than laser polishing”.

With the laser, on the other hand, complex geometries can be polished automatically, reproducibly and significantly faster. While the quality of laser polishing for many applications is already sufficient, the processing speed must be increased even more. “Accelerating laser polishing is currently an important trend, as it makes the process economical for a wide range of applications,” says Willenborg.

Dr.-Ing. Edgar Willenborg

Group Manager Polishing

Telephone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Media Contact

All latest news from the category: Event News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…