Order from the Steel Authority of India: Siemens to supply Rourkela Steel Works with RH vacuum degassing plant

The main functions of the RH degassing plant in the Rourkela Steel Works are the removal of hydrogen, forced decarburization and the chemical heating of the liquid steel. The liquid steel is treated under vacuum conditions with argon as lift gas for circulation of steel. Twenty-four heats can be treated per day, which amounts to a production capacity of about one million tons of liquid steel per annum.

The Siemens RH plant has a capacity of 150 tons, and is designed as a Mono-block design vessel with welded snorkel tubes. The RH-vessel is raised and lowered by a winch system. The scope of supply includes a five-stage vacuum pump, an alloying system, a T-COB (Combined Oxygen Blowing) lance for producing low-carbon types of steel grades, and complete level II process automation. The pressure conditions in the RH vessel are continuously adjustable, which enables the vacuum conditions to be adjusted precisely to the particular requirements of each steel grade, and also reduces the energy requirement. Pre-evacuation shortly before the vacuum treatment accelerates the evacuation of the vessel so the actual metallurgical process can start more quickly. Siemens is also responsible for the design, configuration and construction, as well as for supervising the installation of the RH plant and the associated auxiliary installations.

Rourkela Steel Plant was the first integrated steel plant in the public sector in India and also the first in Asia to adopt the LD technology. This order is unique in the sense that it has re-started the relationship between Siemens VAI and RSP in bringing about further enhancement of technology for production of special grades of steel. The new RH plant is part of SAIL's modernization and expansion program for its Rourkela location, which is intended to increase raw steel production to around 4.2 million tons per year. A third BOF converter will be constructed in steel works II with secondary steelmaking facilities – including the Siemens RH plant, and a continuous slab caster.

Further information about solutions for steel works, rolling mills and processing lines can be found at: http://www.siemens.com/metals

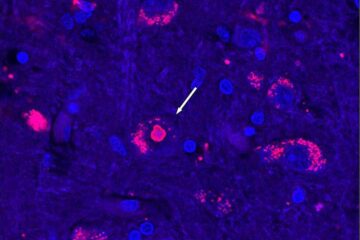

Liquid steel after treatment in a Siemens RH degassing plant

The Siemens Industry Sector (Erlangen, Germany) is the worldwide leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility und Osram. With around 207,000 employees worldwide (September 30), Siemens Industry achieved in fiscal year 2009 total sales of approximately €35 billion. http://www.siemens.com/industry

The Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities comprising the business activities of Siemens VAI Metals Technologies, Water Technologies and Industrial Technologies. Activities include engineering and installation, operation and service for the entire life cycle. A wide-ranging portfolio of environmental solutions helps industrial companies to use energy, water and equipment efficiently, reduce emissions and comply with environmental guidelines. With around 31,000 employees worldwide (September 30), Siemens Industry Solutions posted sales of €6.8 billion in fiscal year 2009.

Siemens AG

Corporate Communications and Government Affairs

Wittelsbacherplatz 2, 80333 Munich

Germany

Reference number: IIS201008.620e fp

Media Relations: Dr. Rainer Schulze

Telephone: +49 9131 7-44544

E-Mail: rainer.schulze@siemens.com

Media Contact

All latest news from the category: Corporate News

Newest articles

Recovering phosphorus from sewage sludge ash

Chemical and heat treatment of sewage sludge can recover phosphorus in a process that could help address the problem of diminishing supplies of phosphorus ores. Valuable supplies of phosphorus could…

Efficient, sustainable and cost-effective hybrid energy storage system for modern power grids

EU project HyFlow: Over three years of research, the consortium of the EU project HyFlow has successfully developed a highly efficient, sustainable, and cost-effective hybrid energy storage system (HESS) that…

After 25 years, researchers uncover genetic cause of rare neurological disease

Some families call it a trial of faith. Others just call it a curse. The progressive neurological disease known as spinocerebellar ataxia 4 (SCA4) is a rare condition, but its…