SpectralFinder Easy-to-use, intuitive and quick hyperspectral distinction of materials

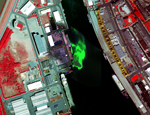

Detection of water pollution by oil

The Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB exhibits the SpectralFinder on CeBIT, Hannover, between March 10 th and 14 th . The mobile system is capable of recording and analyzing large amounts of hyperspectral data in real-time. The exhibit can be found in hall 9, Booth E40.

Which parts of the water surface are contaminated with oil? Is the dike’s vegetation cover intact? Did we find ore, or some type of rock? Did someone use the nature reserve as an illegal dump site for waste?

Man questions demand a reliable distinction of specific materials. Cameras with color sensitive hyperspectral sensors and efficient, innovative processing methods can detect different these materials where the human eye cannot.

Applications for such systems exist where surfaces have to be examined – airborne for environmental monitoring and disaster management, handheld when prospecting or inspecting structures, and also as part of fixed systems such as quality control at production lines.

The human eye only recognizes three different colors across its entire range of color vision: red, green and blue. In comparison, hyperspectral sensors capture more than 100 different color values for each pixel in the image. Processing algorithms use this high spectral resolution to achieve improved distinction between materials. This in turn lowers the false alarm rate for material detection.

State of the art sensor technology even allows the capture of hyperspectral videos. The stream of data to be processed surpasses 1 gigabyte per minute. Fraunhofer IOSB’s extensive experience with large-scale hyperspectral data processing and efficient algorithms allow the results to be available in almost real-time.

Easy-to-use, intuitive and quick

The interactive analysis allows for easy extraction of information by depicting the classification results directly on top of the data stream. The real-time capabilities of these analysis methods can support problem solution in areas where immediate action is necessary.

Employing the SpectralFinder as an airborne system, it can be used for quick reconnaissance, especially for environment protection and disaster management. It is possible to detect oil pollution, weaknesses on levees caused by pest infestation or erosion, as well as illegal garbage disposal.

The SpectralFinder has a compact, lightweight hyperspectral video camera. Its mobility even allows for handheld data acquisition at close range. In quality control of bridges, for example, spectrally suspicious areas can be highlighted and samples can be taken for further analysis.

Mounting the system to a conveyer it is possible to analyze bulk goods. In mining, it is possible to separate chunks of ore from wall rock.

Controlling the SpectralFinder is very intuitive. To compute a classification, the material is recorded with the hyperspectral camera and the data is directly transferred to the software. The user, then, selects an area of interest or a specific material from a database. The following classification is computed with this information, specifically adjusted to the desired purpose. A score is assigned to every pixel in the running video stream to evaluate the similarity between the area of interest and the recorded data. If a 3D model of the scene exists, it is even possible to visualize and work with the data in a virtual laboratory on a desktop computer.

Visitors of the Fraunhofer booth on CeBIT will have the opportunity to experience the SpectralFinder in action and see the intuitive handling and fast data processing in a live demonstration.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…