Automated Laser Material Processing – precise, flexible and time-saving

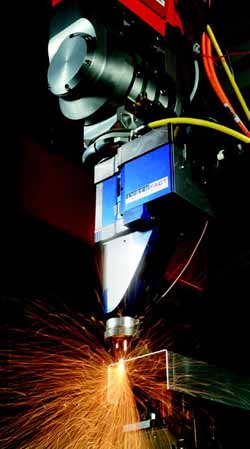

The combi-head cuts and measures the U-shaped section…<br>Fraunhofer Institute for Laser Technology ILT, Aachen<br>

By combining laser cutting and laser welding in a single processing head, the Fraunhofer researchers have created a system that leads to higher flexibility in plant dimensioning, optimizing the processing sequence and reducing the clamping, storage and transport times. To do this, the institute has developed a so-called combi-head, which is produced and marketed by the cooperation partner Laserfact GmbH in Aachen and whose latest functional upgrades will be presented at EuroBLECH 2010.

Thanks to the Tool Center Point, common to both processes, component precision and process stability during laser cutting and welding have been significantly increased. The signals from the capacitive distance sensor system of the combi-head are used for normal distance control as well as for component measurement so as to precisely predetermine the subsequent weld seam.

Combi-head in Integrated Process Chains

In this way, complex sheet metal component parts can be cut to size, measured, welded and finally cut again, all in an integrated process chain. Dr. Dirk Petring, group manager of Macro Joining and Cutting, explains, »The connection of combi-processing and capacitive component measurement is not only suitable for concealed t-joints in structural components of automobile construction, but can also offer new solutions wherever curved or deep-drawn sheet metal parts need to be joined together to create a precise sheet metal group in spite of their geometric tolerances.«

TCP and processing heads were also a part of another process developed at the Fraunhofer ILT: an image processing system »observes« the laser processing position on the workpiece directly through the processing optics – analogous to photography with a single lens reflex camera. The direct surroundings of the processing position are analyzed by a camera system with downstream image processing. »The system measures directly in the area of the processing position and not at the head or in the robot axes,« explains Dipl. Ing. Christoph Franz, scientist at the Fraunhofer ILT. »Since the process gauges the ongoing measurement accuracy, no measurement errors are made.« The measuring system records the current process speed and uncovers deviations from the preset values. It ensures that the processing head follows the contours of the workpiece exactly. According to Franz, »The user receives precise feedback on how the cinematic process parameters comply to the track that was previously programmed into the machine control system. With this process, the tracks of any processing system can be measured.« This is an important point with lasers, for which the so-called energy per unit length has to be constant during the entire processing.

Process Monitoring during »Laser Brazing«

In Hanover a joint development with the Fraunhofer IPT was also exhibited: »Coaxial Process Control (CPC)«, developed specially for laser brazing, takes the process zones under the magnifying glass in the visible and near infrared spectral range (NIR). The visible images deliver data on feed speed, wire position and geometric measurement of the braze seam. The NIR images informs users about the heat distribution in the workpiece, the emergence of pores or about single-sided moistening. »The process monitoring during the laser process makes a further production step – a time-consuming and expensive quality control – superfluous,« says Dipl.-Ing. Michael Ungers, scientist at the Fraunhofer ILT. The following speaks for the CPC model: in comprehensive test series with steel and aluminum working materials, the system was tested and also found suitable for automated process monitoring thanks to special software.

Contact Partners at the Fraunhofer ILT

Our experts would be glad to answer any questions you may have:

Dr. Dirk Petring

Group Manager, Macro Joining and Cutting

Telephone +49 241 8906-210

dirk.petring@ilt.fraunhofer.de

Dipl.-Ing. Christoph Franz

Sensors

Telephone +49 241 8906-621

christoph.franz@ilt.fraunhofer.de

Dipl.-Phys. Michael Ungers

Sensors

Telephone +49 241 8906-281

michael.ungers@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

Tel. +49 241 8906-0

Fax. +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Trade Fair News

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…