Siberian scientists learned how to reduce harmful emissions from HPPs

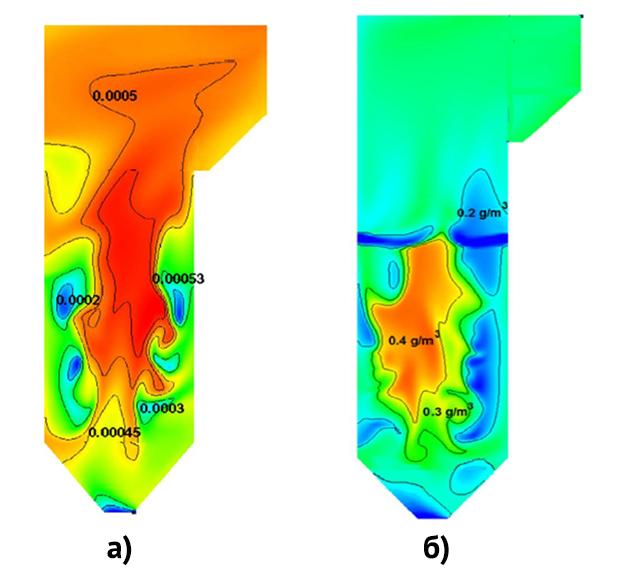

This is the results of modeled distribution of NOx in a combustion chamber: a) regular boiler, kg/m3; b) three-step combustion boiler with the use of mechanically activated micro-milled coal, g/m3 Credit: Alexander Dekterev

Heat power plants (HPPs) supply electrical energy to many cities in the world. The production of heat and electricity starts with burning coal in a combustion chamber. Generated heat warms up the steam and smoke mixture that moves the turbine. This is how electricity is produced, and the warmth is used for heating. However, when coal is burned at HPPs, harmful nitrogen oxides are released into the atmosphere.

One of the most prospective emission-cutting technologies is post-combustion or three-stage fuel combustion. After the first combustion stage during which the main part of the coal burns out and the air is scarce, the remains of the fuel are transferred to a special area above the combustion chamber.

Additional fuel is also transported here. Nitrogen oxides react with the hydrocarbon forming hydrogen cyanide and molecular nitrogen, and the volume of nitrogen oxide emissions drops by about 10%.

“The environmental impact of oil and gas post-combustion is more evident, but we also have to work with coal. It has a great practical importance as many HPPs use it,” explained Alexander Dekterev, a co-author of the article, candidate of technical sciences, and head of the department of thermal physics at SFU.

Many scientists conducted experiments in order to understand which properties of coal and combustion techniques allow for maximum emissions reduction. Recently physicists have offered to mill coal down not to average powder (with particle size of about 200 micron, like in facial powder) but to micro-particles (20-30 micron). This technique provides for a more stable flare in HPPs, as coal micro-particles are mixed better and burned quicker.

Previously this effect was demonstrated in small experimental boilers. The flame from the burning of coal micro-particles resembled that of burning oil, and the particles were almost invisible. Still it wasn't clear whether the effect would be the same in regular HPP boilers, and the scientists from Krasnoyarsk decided to model that.

They took a standard steam boiler BKZ-500-140 of Krasnoyarsk HPP-2 as a model, as all experimental data on it was available. The data were downloaded into the model and after that is was reconfigured taking the post-combustion into account. In the new model the basic fuel was brown Kansk-Achinsk coal, and the post-combustion fuel was formed by jet coal from Kuznetsk. According to initial calculations, the mathematical model implemented by the authors of the article in the in-house software correctly described the processes in the boiler.

The team modeled three burning schemes – with regular coal, micro-particle coal, and mechanically activated fuel. The latter variant proved to be preferable and led to 50% reduction in Nox emissions compared to the basic variant and by 20% to the regular coal.

The work might be of interest for developers and engineers working on the improvement of the existing boiler equipment and design of power blocks. The authors continue to develop mathematical modeling methods to improve burning technologies both for widely used and unconventional fuel types.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…