Perovskites provide big boost to silicon solar cells, Stanford study finds

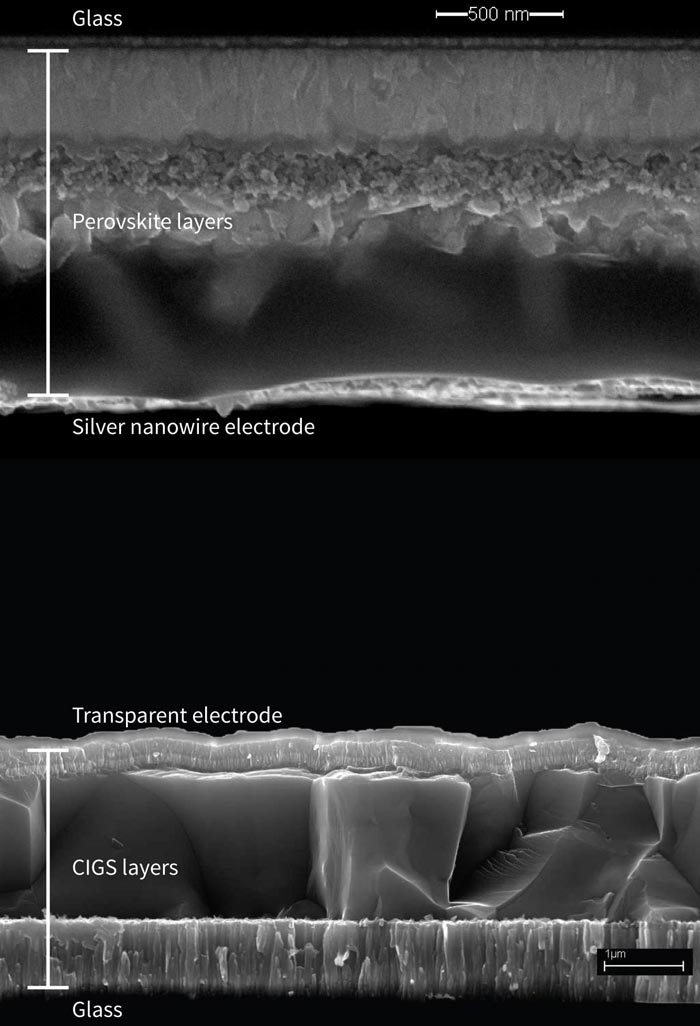

This is a microscopic cross-section of a tandem solar cell made with two photovoltaic materials, perovskite and copper indium gallium diselenide, or CIGS. Credit: Colin Bailie, Stanford University

The researchers describe their novel perovskite-silicon solar cell in this week's edition of the journal Energy & Environmental Science.

“We've been looking for ways to make solar panels that are more efficient and lower cost,” said study co-author Michael McGehee, a professor of materials science and engineering at Stanford. “Right now, silicon solar cells dominate the world market, but the power conversion efficiency of silicon photovoltaics has been stuck at 25 percent for 15 years.”

One cost-effective way to improve efficiency is to build a tandem device made of silicon and another inexpensive photovoltaic material, he said.

“Making low-cost tandems is very desirable,” McGehee said. “You simply put one solar cell on top of the other, and you get more efficiency than either could do by itself. From a commercial standpoint, it makes a lot of sense to use silicon for the bottom cell. Until recently, we didn't have a good material for the top cell, then pervoskites came along.”

Perovskite is a crystalline material that is inexpensive and easy to produce in the lab. In 2009, scientists showed that perovskites made of lead, iodide and methylammonium could convert sunlight into electricity with an efficiency of 3.8 percent. Since then, researchers have achieved perovskite efficiencies above 20 percent, rivaling commercially available silicon solar cells and spawning widespread interest among silicon manufacturers.

“Our goal is to leverage the silicon factories that already exist around the world,” said Stanford graduate student Colin Bailie, co-lead author of the study. “With tandem solar cells, you don't need a billion-dollar capital expenditure to build a new factory. Instead, you can start with a silicon module and add a layer of perovskite at relatively low cost.”

Sunlight to electricity

Solar cells work by converting photons of sunlight into an electric current that moves between two electrodes. Silicon solar cells generate electricity by absorbing photons of visible and infrared light, while perovskite cells harvest only the visible part of the solar spectrum where the photons have more energy.

“Absorbing the high-energy part of the spectrum allows perovskite solar cells to generate more power per photon of visible light than silicon cells,” Bailie said.

A key roadblock to building an efficient perovskite-silicon tandem has been a lack of transparency.

“Colin had to figure out how to put a transparent electrode on the top so that some photons could penetrate the perovskite layer and be absorbed by the silicon at the bottom,” McGehee said. “No one had ever made a perovskite solar cell with two transparent electrodes.”

Perovskites are easily damaged by heat and readily dissolve in water. This inherent instability ruled out virtually all of the conventional techniques for applying electrodes onto the perovoskite solar cell, so Bailie did it manually.

“We used a sheet of plastic with silver nanowires on it,” he said. “Then we built a tool that uses pressure to transfer the nanowires onto the perovskite cell, kind of like a temporary tattoo. You just need to rub it to transfer the film.”

Remarkable efficiency

For the experiment, the Stanford team stacked a perovskite solar cell with an efficiency of a 12.7 percent on top of a low-quality silicon cell with an efficiency of just 11.4 percent.

“By combining two cells with approximately the same efficiency, you can get a very large efficiency boost,” Bailie said.

The results were impressive.

“We improved the 11.4 percent silicon cell to 17 percent as a tandem, a remarkable relative efficiency increase of nearly 50 percent,” McGehee said. “Such a drastic improvement in efficiency has the potential to redefine the commercial viability of low-quality silicon.”

In another experiment, the research team replaced the silicon solar cell with a cell made of copper indium gallium diselenide (CIGS). The researchers stacked a 12.7 percent efficiency perovskite cell onto a CIGS cell with a 17 percent efficiency. The resulting tandem achieved an overall conversion efficiency of 18.6 percent.

“Since most, if not all, of the layers in a perovskite cell can be deposited from solution, it might be possible to upgrade conventional solar cells into higher-performing tandems with little increase in cost,” the authors wrote.

A big unanswered question is the long-term stability of perovskites, McGehee added.

“Silicon is a rock,” he said. “You can heat it to about 600 degrees Fahrenheit shine light on it for 25 years and nothing will happen. But if you expose perovskite to water or light it likely will degrade. We have a ways to go to show that perovskite solar cells are stable enough to last 25 years. My vision is that some day we'll be able to get low-cost tandems that are 25 percent efficient. That's what companies are excited about. In five to 10 years, we could even reach 30 percent efficiency.”

The study was also written by co-lead author M. Greyson Christoforo, Andrea Bowring, Eva Unger, William Nguyen and Alberto Salleo from Stanford; Jonathan Mailoa, Jungwoo Lee and Tonio Buonassisi from the Massachusetts Institute of Technology; Julian Burschka, Norman Pellet and Michael Graetzel from the Swiss École Polytechnique Fédérale de Lausanne; and Rommel Noufi, formerly with the U.S. National Renewable Energy Laboratory.

This article was written by Mark Shwartz, Precourt Institute for Energy at Stanford University.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…