Liberating devices from their power cords

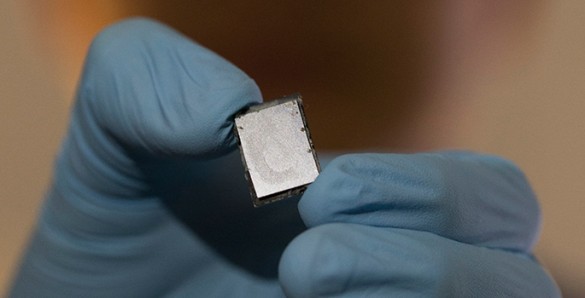

Close-up of structural supercapacitor. (Joe Howell / Vanderbilt)

This intriguing prospect is one of the reasons for the current interest in building the capacity to store electrical energy directly into a wide range of products, such as a laptop whose casing serves as its battery, or an electric car powered by energy stored in its chassis, or a home where the dry wall and siding store the electricity that runs the lights and appliances.

It also makes the small, dull grey wafers that graduate student Andrew Westover and Assistant Professor of Mechanical Engineering Cary Pint have made in Vanderbilt’s Nanomaterials and Energy Devices Laboratory far more important than their nondescript appearance suggests.

“These devices demonstrate – for the first time as far as we can tell – that it is possible to create materials that can store and discharge significant amounts of electricity while they are subject to realistic static loads and dynamic forces, such as vibrations or impacts,” said Pint. “Andrew has managed to make our dream of structural energy storage materials into a reality.”

When you can integrate energy into the components used to build systems, it opens the door to a whole new world of technological possibilities.That is important because structural energy storage will change the way in which a wide variety of technologies are developed in the future. “When you can integrate energy into the components used to build systems, it opens the door to a whole new world of technological possibilities. All of a sudden, the ability to design technologies at the basis of health, entertainment, travel and social communication will not be limited by plugs and external power sources,” Pint said.

The new device that Pint and Westover has developed is a supercapacitor that stores electricity by assembling electrically charged ions on the surface of a porous material, instead of storing it in chemical reactions the way batteries do. As a result, supercaps can charge and discharge in minutes, instead of hours, and operate for millions of cycles, instead of thousands of cycles like batteries.

In a paper appearing online May 19 in the journal Nano Letters, Pint and Westover report that their new structural supercapacitor operates flawlessly in storing and releasing electrical charge while subject to stresses or pressures up to 44 psi and vibrational accelerations over 80 g (significantly greater than those acting on turbine blades in a jet engine).

Furthermore, the mechanical robustness of the device doesn’t compromise its energy storage capability. “In an unpackaged, structurally integrated state our supercapacitor can store more energy and operate at higher voltages than a packaged, off-the-shelf commercial supercapacitor, even under intense dynamic and static forces,” Pint said.

One area where supercapacitors lag behind batteries is in electrical energy storage capability: Supercaps must be larger and heavier to store the same amount of energy as lithium-ion batteries. However, the difference is not as important when considering multifunctional energy storage systems.

Supercapacitors store ten times less energy than current lithium-ion batteries, but they can last a thousand times longer.“Battery performance metrics change when you’re putting energy storage into heavy materials that are already needed for structural integrity,” said Pint. “Supercapacitors store ten times less energy than current lithium-ion batteries, but they can last a thousand times longer. That means they are better suited for structural applications. It doesn’t make sense to develop materials to build a home, car chassis, or aerospace vehicle if you have to replace them every few years because they go dead.”

Westover’s wafers consist of electrodes made from silicon that have been chemically treated so they have nanoscale pores on their inner surfaces and then coated with a protective ultrathin graphene-like layer of carbon. Sandwiched between the two electrodes is a polymer film that acts as a reservoir of charged ions, similar to the role of the electrolyte paste in a battery. When the electrodes are pressed together, the polymer oozes into the tiny pores in much the same way that melted cheese soaks into the nooks and crannies of artisan bread in a panini. When the polymer cools and solidifies, it forms an extremely strong mechanical bond.

“The biggest problem with designing load-bearing supercaps is preventing them from delaminating,” said Westover. “Combining nanoporous material with the polymer electrolyte bonds the layers together tighter than superglue.”

The use of silicon in structural supercapacitors is best suited for consumer electronics and solar cells, but Pint and Westover are confident that the rules that govern the load-bearing character of their design will carry over to other materials, such as carbon nanotubes and lightweight porous metals like aluminum.

The intensity of interest in “multifunctional” devices of this sort is reflected by the fact that the U.S. Department of Energy’s Advanced Research Project Agency for Energy is investing $8.7 million in research projects that focus specifically on incorporating energy storage into structural materials. There have also been recent press reports of several major efforts to develop multifunctional materials or structural batteries for use in electric vehicles and for military applications. However, Pint pointed out that there have not been any reports in the technical literature of tests performed on structural energy storage materials that show how they function under realistic mechanical loads.

Amrutur Anilkumar, professor of the practice in mechanical engineering, postdoctoral associate Shahana Chatterjee, graduate student Landon Oakes, undergraduate mechanical engineering majors John Tian, Shivaprem Bernath and Farhan Nur Shabab and high school student Rob Edwards collaborated in the project.

The research was supported by National Science Foundation grants CMMI 1334269 and EPS 104083. Materials fabrication was conducted in part at the Center for Nanophase Materials Sciences at Oak Ridge National Laboratory that is supported by the Office of Basic Energy Sciences of the U.S. Department of Energy.

Contact:

David Salisbury, (615) 322-NEWS

david.salisbury@vanderbilt.edu

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…