Altos Hornos de Mexico orders RH plant from Siemens

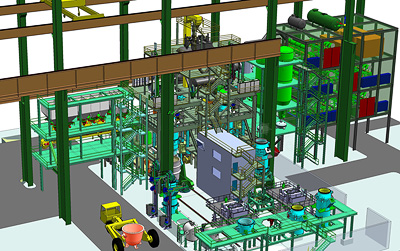

Computer animated diagram of a double RH vacuum degassing plant from Siemens. An RH plant with a processing capacity of two million metric tons of liquid steel per annum will be constructed in Monclova, Mexico, for Altos Hornos de Mexico (AHMSA).

Siemens Metals Technologies has won an order from Mexican steel producer Altos Hornos de Mexico, S.A.B. de C.V. (AHMSA) to supply a 150-ton, twin RH vacuum degassing plant with mechanical vacuum pumps for converter Steel Works # 2 in Monclova.

It will be able to handle 50 charges per day, the equivalent of about two million metric tons of liquid steel per year. The new plant will allow AHMSA to produce steels with very low hydrogen content, required for applications in the oil and gas industries. The new RH plant is scheduled for commissioning in October 2015.

The main functions of RH degassing plants are the removal of hydrogen, forced decarburization and the chemical heating of the liquid steel which is processed under vacuum conditions with the injection of oxygen. Low hydrogen content is the main prerequisite for producing high-strength steel grades intended for use in the oil and gas industries.

For AHMSA's twin RH plant in Monclova, in the state of Coahuila, Siemens will supply the vessel, mechanical vacuum pumps, the structural steel work and a combined vessel ladle lifting system (CVL). This solution requires little space, enabling vessels to be lifted in places inaccessible to cranes. The scope of supply from Siemens also includes the electrical and automation equipment for the RH plant.

With an annual production of 4.2 million metric tons of liquid steel; which, upon the start-up of its new Electric Arc Furnace in September 2014, its production will increase to 5.5 million metric tons, AHMSA operates the largest integrated steel works in Mexico. The company is the market leader in the production and marketing of flat products, such as hot and cold strip, and tinplate. The product portfolio also includes heavy-sections.

Further information about solutions for steel works, rolling mills and processing lines can be found at www.siemens.com/metals.

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of innovative and environmentally friendly products and solutions for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the Sector enhances its customers' productivity, efficiency, and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit http://www.siemens.com/industry

The Metals Technologies Business Unit (Linz, Austria), part of the Siemens Industry Sector, is one of the world's leading life-cycle partners for the metals industry. The Business Unit offers a comprehensive technology, modernization, product and service portfolio as well as integrated automation and environmental solutions covering the entire life cycle of plants. For more information, visit http://www.siemens.com/metals

Reference Number: IMT201407658e

Mr. Rainer Schulze

Metals Technologies

Siemens AG

Turmstr. 44

4031 Linz

Austria

Tel: +49 (9131) 7-44544

All latest news from the category: Corporate News

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…