Less than nine months from signature to caster start-up – New billet caster concept from Siemens shortens project time

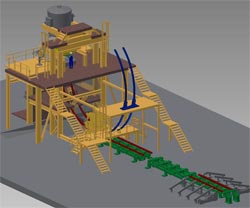

Schematic overview of the basic two-strand billet caster variant with a production<br>capacity of 200,000 t/a<br>

On the basis of a reengineered plant design, complimented by an extended logistics and sourcing network, billet casting projects can be completed more quickly, efficiently and at lower costs in comparison with conventional engineering and plant-building concepts.

The availability of different caster machine variants in combination with modular plant expandability allows producers to tailor their plants to current and future market requirements.

The highly compact plant design with a bow radius of six meters foresees the installation of one to four billet strands, each with an annual casting capacity of approximately 100,000 tons of carbon steel grades. Operation of the individual strands can be carried out independently of each other, thus assuring optimum caster utilization in accordance with the availability of liquid steel. Strand formats range from 100×100 mm to 200×200 mm. The cast products will be typically rolled to bars and wires for infrastructural applications.

All construction elements, machine components and systems are modularly designed and preassembled in the workshop to the greatest extent possible. Installation of equipment and technological packages is based on the Siemens VAI Connect & Cast principle, ensuring that plant functions and systems are fully operational from the first heat on. In this way, erection, start-up and commissioning can be completed within several weeks. Caster upgrading and expansion is carried out in steps depending on customer and market requirements. The extensive worldwide network of Siemens workshop and service centers, supported by regional manufacturing resources, ensures that equipment and components can be quickly delivered to the plant site. This new generation of economy billet casters with notably short installation periods allows local and emerging companies to quickly respond to rapidly changing market demands for steel.

Further information about solutions for steel works, rolling mills and processing lines is available at http://www.siemens.com/metals

Connect & Cast is a registered trademark of Siemens VAI Metals Technologies GmbH

The Siemens Industry Sector (Erlangen, Germany) is the worldwide leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility and Osram. With around 204,000 employees worldwide (September 30), Siemens Industry achieved in fiscal year 2010 total sales of approximately €34.9 billion. www.siemens.com/industry

The Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities comprising the business activities of Siemens VAI Metals Technologies, Water Technologies and Industrial Technologies. Activities include engineering and installation, operation and service for the entire life cycle. A wide-ranging portfolio of environmental solutions helps industrial companies to use energy, water and equipment efficiently, reduce emissions and comply with environmental guidelines. With around 29,000 employees worldwide (September 30), Siemens Industry Solutions posted sales of €6.0 billion in fiscal year 2010.

www.siemens.com/industry-solutions

Media Contact

More Information:

http://www.siemens.com/metalsAll latest news from the category: Corporate News

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…