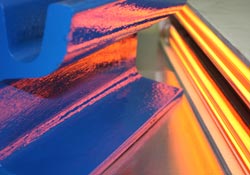

Paint and Lacquer Curing – Infrared Emitters and UV Lamps Provide an Efficient Combination

Infrared heat dries, UV radiation cures – tests in our Application Centre help to define the necessary parameters.<br><br>Copyright Heraeus Noblelight, Hanau 2014<br>

However, for the manufacturer, this can present real challenges, as very often these manufacturing steps can be costly and energy-demanding.

Heraeus Noblelight is showing application-focused UV lamps, infrared emitters and systems for coating curing at the PaintExpo exhibition in Karlsruhe in April. Examples of applications will show when and where a combination of UV and IR can be beneficial and what parameters must be observed.

Infrared transfers energy to materials without contact, generates heat where it is required and consequently is especially efficient in the drying of varnishes or the melting of powder coatings. In a UV curing process, polymerization, photo-initiators are activated by intensive UV light and cured in a fraction of a second.

As a result, the material is cured very quickly and the surface is dry, wear-resistant and can be subjected to further processes immediately. In some applications, the curing can be optimized and carried out more efficiently by a combination of infrared heat with UV radiation. These applications include high quality surface coatings and surfaces which must be scratch resistant.

Plastic surface are given a scratch-free coating, to impart a mirror finish. Fingerprint-resistance prevents smearing of the highly polished surfaced by fingerprints, hand cream or suntan lotions. Such coatings are often UV coatings, which need UV radiation to initiate the cross-linkage. This cross-linkage reaction occurs more efficiently at higher temperatures and can be further optimized by pre- or post-heating. For this reason, some plastic components such as radio fascias, gear sticks or lipstick casings are often pre-heated with infrared. This provides an improvement in the coating properties.

Infrared Emitters Provide Very Efficient Curing of Coatings on Many Materials

Infrared heating has already proved successful in the drying of coatings, as infrared radiation penetrates into the material, at a depth depending on the material, and dries the coating film from the inside outwards. Skin or bubble-formation on the surface is prevented and coating drying is accelerated. The result is a brilliant surface quality. Infrared emitters transfer heat in a contact-free and efficient manner, with the aid of electromagnetic waves, which generate the heat first in the coated material. Unlike hot air systems, infrared heating minimizes the adhesion of spurious particles in the sensitive coating during drying.

Radiation, which is precisely matched to the product and coating, is quickly converted into heat where it is required. It vaporizes water or other solvents, while the material and the immediate environment remain cooler. For example, medium wave infrared radiation is particularly well absorbed by water. Consequently, it is particularly good for water-based coatings.

IR heating is also ideal for web substrates such as paper, textiles and foils, where IR heat dries coatings within seconds. IR heat dries large three dimensional objects such as engine blocks or metal housings faster than some hot air systems, as metal is a very good conductor of heat and infrared emitters transfer large amounts of energy in a very short time.

UV Lamps Cure in Seconds in a Targeted Fashion

UV radiation allows UV paints, lacquers and adhesives to cure very quickly. In contrast to conventional coatings UV formulations contain little or no solvents. In a UV curing process, polymerization, photo-initiators are activated by intensive UV light. Chemical compounds are then broken down and then cross link to form new compounds. In fractions of a second, the cross-linked system is dry and abrasion-proof and is suitable for further processing.

Today, there are already light sources doped with Gallium or mercury. Their wavelengths determine the point of the curing: in the depth of the coating or on the surface. The optimum curing process is affected by different factors. The emission spectrum and intensity of the UV light source, the carrier material and ambient temperature, the nature and thickness of the material to be cured, the process speed, the distance between the material and the UV light source and, naturally, the chemical composition of the coating system must all be taken into consideration. UV light sources, precisely matched to the process, improve reliability as well as process speed, reduce the material loading and save both costs and energy.

When Should a Combination of Infrared Heat and UV Technology Be Considered?

Heat improves the mobility of molecules and so improves the curing reaction. Many processes introduce only a little heat into the coating materials, sometimes when the process runs very fast. This can be detrimental to the adhesion and stability of the coating.

UV curing is a chemical cross-linking process. By pre-heating the substrate with infrared radiation there is better adhesion and cross-linking of UV coatings. It has been shown to be beneficial to heat materials in a targeted fashion before the UV cross linking.

Infrared heat is also used to drive solvents from high gloss UV coating before curing. This is especially important with modern, water-based wet coatings. Here infrared heat is used to vaporize the water, so that the following UV radiation can cross-link the coating optimally.

A combination of IR and UV should then be considered when excellent quality is demanded or energy needs to be saved. By the innovative combination of infrared heat with UV technology the energy efficiency of the coating curing is improved on one hand and the cross-linking of UV coatings is optimized on the other hand.

The precious metals and technology group Heraeus headquartered in Hanau, Germany, is a global, family company with over 160 years of tradition. Our businesses include precious metals, materials and technologies, sensors, biomaterials and medical products, quartz glass, and specialty lighting sources. With product revenues of € 4.2 billion and precious metal trading revenues of € 16 billion in 2012, Heraeus has around 12,200 employees in more than 100 companies worldwide and holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources. In 2012, Heraeus Noblelight had an annual turnover of 92.5 Million € and employed 715 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

Heraeus Noblelight acquired the Fusion UV Systems Group, headquartered in Gaithersburg, Maryland, USA, on 31 January 2013.

For further information, please contact:

Technical: Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press: Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Abteilung Marketing/Werbung

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

More Information:

http://www.heraeus-noblelight.com/infraredAll latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…