CeBIT: Automated microscopy in the MicroLab

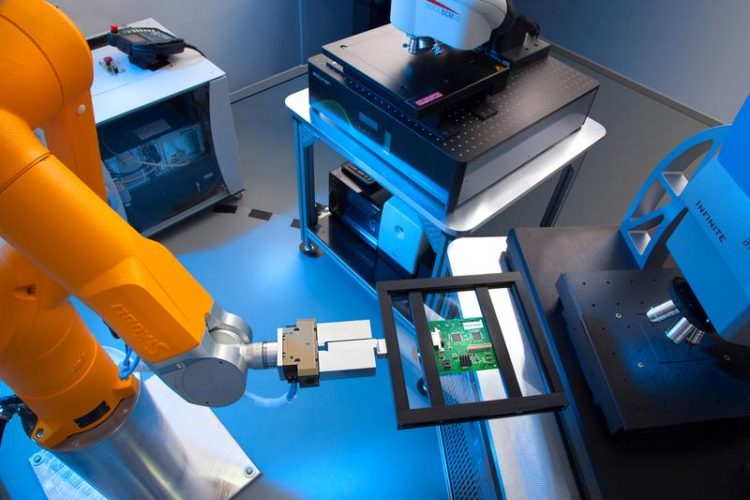

In MicroLab a robot handles the sample on the microscopes. Photo: Manfred Zentsch © Fraunhofer IOSB 2013

Microelectronics is one of the most important industries of our high-tech world. More and more products are equipped with computer technology. Used mainly in computers only a few years ago, processors can today be found in medical systems, watches, glasses, smart textiles, vehicles, and in building automation systems. The entertainment and communication technology is booming in our interconnected world. Meanwhile, microelectronics have arrived at the nanoscale, the components being so tiny that a processor fits into the size of a pinhead. This places high demands on production.

Fraunhofer IOSB has long been concerned with automated image analysis for quality assurance in production, and especially with the inspection of surfaces. The idea was born of transferring this knowledge to the world of microscope imaging. A demonstration and test environment was developed for fully automated inspection with various microscopes, which were combined using established automation components. In MicroLab a range of optical microscopes are available as examples. Currently they include a macroscope with flexible lighting options, a white-light/confocal microscope, a research microscope, and a 3D-reconstructing autofocus system.

Robot as operator

The microscopes are operated by a standard six-axis industrial robot, which places the samples under the microscopes precisely in a defined position. Project manager Peter Frühberger explains: “The robot is connected to a central control unit, which can access additional sensors. The inspection system therefore remains informed about the current process and can intelligently steer the inspection sequence. Test sequences are distributed over the microscopes, so that, wherever possible, all systems can be used simultaneously.” This saves time and yields results that are optimized for the respective inspection task.

Modular design

MicroLab is deliberately composed of standard automation technology components. This permits its use as a complete system for inspection, analysis, and quality assurance for a wide range of objects and surfaces. The range of available microscopes ensures that a wide range of tasks can be solved. The combined use of several microscopes, furthermore, opens new possibilities in applications for which individual microscopes would not suffice. Because of its modular design, selected components of MicroLab could easily be incorporated in existing systems.

Another advantage of MicroLab is that industry customers can test various microscopes in their application to determine which is best suited and how to best integrate it into the existing installation.

MicroLab also benefits from the extensive experience of IOSB in the field of image processing. Established methods from the fields of image fusion and photometric stereo imaging have been transferred to the microscopic dimension.

The adaptation of such proven practices pays a significant contribution to successfully putting modular and industry-capable microscopic inspection systems into industrial use.

At CeBIT 2014, part of MicroLab will be presented to the public for the first time. It can be seen in Hall 9 at the Fraunhofer stand.

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Trotting robots reveal emergence of animal gait transitions

A four-legged robot trained with machine learning by EPFL researchers has learned to avoid falls by spontaneously switching between walking, trotting, and pronking – a milestone for roboticists as well…

Innovation promises to prevent power pole-top fires

Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts. Pole-top fires pose…

Possible alternative to antibiotics produced by bacteria

Antibacterial substance from staphylococci discovered with new mechanism of action against natural competitors. Many bacteria produce substances to gain an advantage over competitors in their highly competitive natural environment. Researchers…