power DRUM – Significant improvement of milling efficiency through innovative drum design

The milling efficiency of agitator ball mills depends largely

on the relative velocity of grinding bodies and material. However, the low relative velocity of material in the vicinity of the drum wall causes tranquilising of the mixture of grinding bodies and materials. This effect is particular pronounced at high rotor speed. A new design for the milling drum, developed at the University of Siegen, overcomes this problem and allows significant improvement of the efficiency of agitator ball mills.

Further Information: PDF

PROvendis GmbH

Phone: +49 (0)208/94105 10

Contact

Dipl.-Ing. Alfred Schillert

Media Contact

All latest news from the category: Technology Offerings

Newest articles

Recovering phosphorus from sewage sludge ash

Chemical and heat treatment of sewage sludge can recover phosphorus in a process that could help address the problem of diminishing supplies of phosphorus ores. Valuable supplies of phosphorus could…

Efficient, sustainable and cost-effective hybrid energy storage system for modern power grids

EU project HyFlow: Over three years of research, the consortium of the EU project HyFlow has successfully developed a highly efficient, sustainable, and cost-effective hybrid energy storage system (HESS) that…

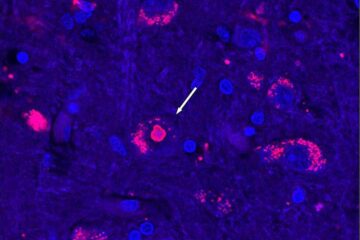

After 25 years, researchers uncover genetic cause of rare neurological disease

Some families call it a trial of faith. Others just call it a curse. The progressive neurological disease known as spinocerebellar ataxia 4 (SCA4) is a rare condition, but its…