When graphene speaks, scientists can now listen

Rice University researchers have discovered that sound can be used to analyze the properties of laser-induced graphene in real time. The technique could be useful for material characterization in a wide range of engineering and manufacturing processes.

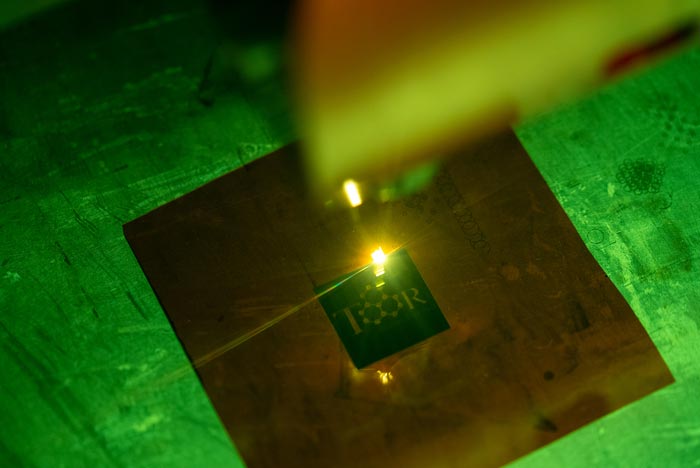

Credit: Brandon Martin/Rice University

Brothers in Rice lab find audio from graphene production contains valuable data.

It may be true that seeing is believing, but sometimes hearing can be better.

Case in point: Two brothers in a Rice University laboratory heard something unusual while making graphene. Ultimately, they determined the sound itself could give them valuable data about the product.

The brothers, John Li, a Rice alumnus now studying at Stanford University, and Victor Li, then a high school student in New York and now a freshman at the Massachusetts Institute of Technology, are co-lead authors of a paper that describes the real-time analysis of laser-induced graphene (LIG) production through sound.

The brothers were working in the lab of Rice chemist James Tour when they came up with their hypothesis and presented it at a group meeting.

“Professor Tour said, ‘It is interesting,’ and told us to pursue it as a potential project,” John Li recalled.

The results, which appear in Advanced Functional Materials, describe a simple acoustic signal processing scheme that analyzes LIG in real time to determine its form and quality.

LIG, introduced by the Tour lab in 2014, makes layers of interconnected graphene sheets by heating the top of a thin polymer sheet to 2,500 degrees Celsius (4,532 degrees Fahrenheit), leaving only carbon atoms behind. The technique has since been applied to making graphene from other feedstock, even food.

“Under different conditions, we hear different sounds because different processes are occurring,” John said. “So if we hear variations during the synthesis, we’d be able to detect different materials being formed.”

He said audio analysis allows for “far greater quality control capabilities that are orders of magnitude faster than characterization of laser-induced graphene by microscopy techniques.

“In materials analysis, there are often tradeoffs between cost, speed, scalability, accuracy and precision, especially in terms of how much material you can systematically process,” John said. “What we have here allows us to efficiently scale the throughput of our analytical capabilities to the entire amount of material we’re trying to synthesize in a robust manner.”

John invited his younger brother to Houston, knowing his expertise would be a plus in the lab. “We have complementary skill sets almost by design, where I avoid specializing in the things that he knows very well, and likewise, he avoids areas that I know very well,” he said. “So we form a very solid team.

“Basically, I made the connection that the right sounds correspond to the right product, and he made the connection that the different sounds corresponded to different products,” he said. “Also, he is much stronger than I am at certain computational techniques, whereas I’m primarily an experimentalist.”

A small, $31 microphone from Amazon taped to the laser head and attached to a cellphone inside the laser cabinet picks up the audio for analysis.

“The brothers converted the sound pattern through a mathematical technique called a Fast Fourier transform, so they could get numerical data from the sound data,” Tour said. “Through some mathematical computations, that data can be a near-instant analytical tool to assess the product type and purity.”

John Li said the sounds emitted “provide information on the relaxation of the energy input when the laser hits the sample and gets absorbed, transmitted, scattered, reflected or just in general converted into different types of energy. That allows us to get local information on properties of the graphene’s microstructure, morphology and nanoscale characteristics.”

Tour remains impressed by their ingenuity.

“What these brothers came up with is amazing,” he said. “They are hearing the sounds of synthesis as it is performed, and from that they can determine product type and quality near-instantaneously. This could be an important approach during synthesis to guide manufacturing parameters.”

He said sound analysis could contribute to a number of manufacturing processes, including his own lab’s flash Joule heating, a method to make graphene and other materials from waste products, as well as sintering, phase engineering, strain engineering, chemical vapor deposition, combustion, annealing, laser-cutting, gas evolution, distillation and more.

“Between John’s experimental expertise and Victor’s mathematical talent, the family team is formidable,” Tour said. “My greatest joy is to provide an atmosphere where young minds can create and flourish, and in this case, they demonstrated expertise way beyond their years, John being only 19 and Victor 17 at the time of their discovery.”

Co-authors of the paper are Rice graduate students Jacob Beckham and Weiyin Chen, postdoctoral researcher Bing Deng, alumnus Duy Luong and research scientist Carter Kittrell. Tour is the T.T. and W.F. Chao Chair in Chemistry as well as a professor of computer science and of materials science and nanoengineering.

The Air Force Office of Scientific Research (FA9550-19-1-0296) supported the research.

Read the abstract at https://onlinelibrary.wiley.com/doi/10.1002/adfm.202110198.

This news release can be found online at https://news.rice.edu/news/2022/when-graphene-speaks-scientists-can-now-listen.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Tour Group: https://www.jmtour.com

Department of Chemistry: https://chemistry.rice.edu

Wiess School of Natural Sciences: https://naturalsciences.rice.edu

Video:

Video produced by Brandon Martin/Rice University

Images for download:

https://news-network.rice.edu/news/files/2022/01/0124_SOUND-5-WEB-james-and-victor.jpg

CAPTION: John, left, and Victor Li.

https://news-network.rice.edu/news/files/2022/01/0124_SOUND-1-web.jpg

Rice University researchers have discovered that sound can be used to analyze the properties of laser-induced graphene in real time. The technique could be useful for material characterization in a wide range of engineering and manufacturing processes. (Credit: Brandon Martin/Rice University)

https://news-network.rice.edu/news/files/2022/01/0124_SOUND-2-web.jpg

Alex Lathem, an applied physics graduate student at Rice University, prepares a sample for lasing. The lab is using sound to analyze the synthesis of laser-induced graphene in real time. (Credit: Brandon Martin/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 4,052 undergraduates and 3,484 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 1 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

Journal: Advanced Functional Materials

DOI: 10.1002/adfm.202110198

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: Sounds of Synthesis: Acoustic Real-Time Analysis of Laser-Induced Graphene

Article Publication Date: 13-Jan-2022

COI Statement: Rice University owns intellectual property on LIG. Some of that property is licensed to a company in which J.M.T. is a stockholder, though not an officer or director. Conflicts of interest are managed through regular disclosures to the Rice University Office of Sponsored Programs and Research Compliance.

Media Contacts

Mike Williams

Rice University

mikewilliams@rice.edu

Office: 713-348-6728

Jeff Falk

Rice University

jfalk@rice.edu

Office: 713-348-6775

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Faster, more energy-efficient way to manufacture an industrially important chemical

Zirconium combined with silicon nitride enhances the conversion of propane — present in natural gas — needed to create in-demand plastic, polypropylene. Polypropylene is a common type of plastic found…

Energy planning in Ghana as a role model for the world

Improving the resilience of energy systems in the Global South. What criteria should we use to better plan for resilient energy systems? How do socio-economic, technical and climate change related…

Artificial blood vessels could improve heart bypass outcomes

Artificial blood vessels could improve heart bypass outcomes. 3D-printed blood vessels, which closely mimic the properties of human veins, could transform the treatment of cardiovascular diseases. Strong, flexible, gel-like tubes…