Augmented reality system facilitates manual manufacturing of products made of fiber-reinforced composite materials

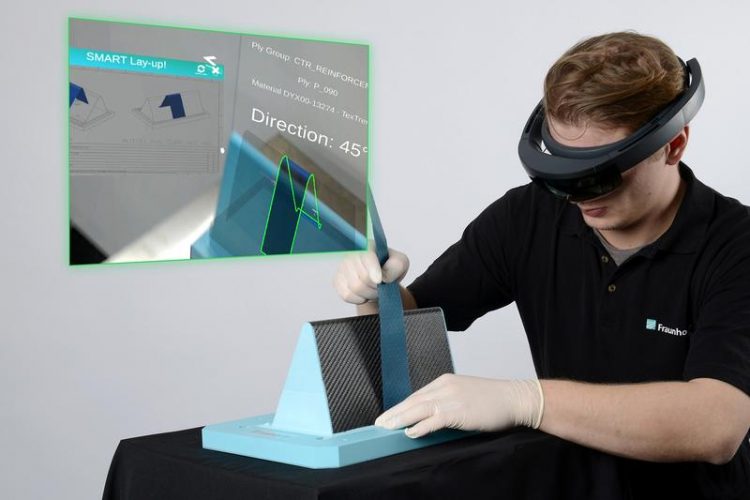

The Fraunhofer IPT has developed software for commercially available smart glasses that specifies the correct deposition of the semi-finished materials as a virtual representation on the mold. Foto: Fraunhofer IPT

The system specifies the correct deposition of the semi-finished materials as a virtual representation on the mold and can thus significantly improve the quality and performance of FRP production processes. For the draping operation of semi-finished fiber materials for component manufacturing and repair, information on the position and orientation of the fiber layers has so far been provided in the form of plybooks:

Small and medium-sized companies frequently work with printed paper instructions and are highly dependent on the experience of the person performing the work. Larger companies, for example in the aerospace industry, have already turned to laser projection systems which project the position of the semi-finished product onto the mold.

These assist the staff to position the semi-finished materials appropriately. However, such laser-based support systems are comparatively expensive and inflexible in their application.

Digital instructions and documentation directly on the component

The Fraunhofer IPT has developed an alternative to these two working aids as part of the Fraunhofer “Smart-Lay-Up!” project: Augmented reality software that uses commercially available smart glasses to make the exact alignment and positioning of the semi-finished materials directly visible on the component.

The cutting of the semi-finished materials is also supported by projection of target contours. This cost-effective system is much more flexible in terms of handling than conventional procedures using paper or laser-based projection systems and is also fully scalable in the production environment, making it suitable for the serial production of FRP products.

The application developed by the Fraunhofer IPT provides the worker wearing the smart glasses with much more than just a digital version of the plybook: it also offers an augmented reality environment in which the information for aligning the fiber layers or pre-impregnated fiber prepregs is placed directly above the component in front of them. Step-by-step instructions guide the worker through the preforming process and, if required, document the work for quality assurance purposes.

The software can be easily installed as an app on data glasses with an Android operating system and can be adapted for the lay-up task in hand. Companies wishing to try out and use the technology can now test the app in a feasibility study with their own production staff and identify individual requirements in collaboration with Fraunhofer IPT employees.

Cost-effective system for manufacturers of individual lightweight products

The Aachen researchers predict that the new technology will improve the accuracy and traceability of the processing of components made of fiber-reinforced high-performance materials, reduce the error rate and significantly shorten process times. The acquisition of the smart glasses-based system, which costs less than a tenth of the costly laser projection systems, will thus also become affordable for small and medium-sized companies and can lead to noticeable productivity improvements in markets such as medical technology, boat building, mechanical engineering, but also in the manufacture of upmarket consumer products made of fiber-reinforced lightweight materials.

During the JEC Composites World 2020, the international trade fair for composite materials and technologies from May 12 to 14 in Paris, the researchers of the Fraunhofer IPT will be presenting a demonstrator system consisting of a Microsoft HoloLens with the newly developed software on a test stand for hand lay-up to the trade fair visitors at Booth L97 in Hall 5.

Martin Schäkel M.Sc.

Fraunhofer Institute for Production Technology IPT

Steinbachstrasse 17

52074 Aachen, Germany

Telefon +49 241 8904-147

martin.schaekel@ipt.fraunhofer.de

https://www.ipt.fraunhofer.de/en/Press/Pressreleases/20200303-augmented-reality-…

Media Contact

All latest news from the category: Trade Fair News

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…