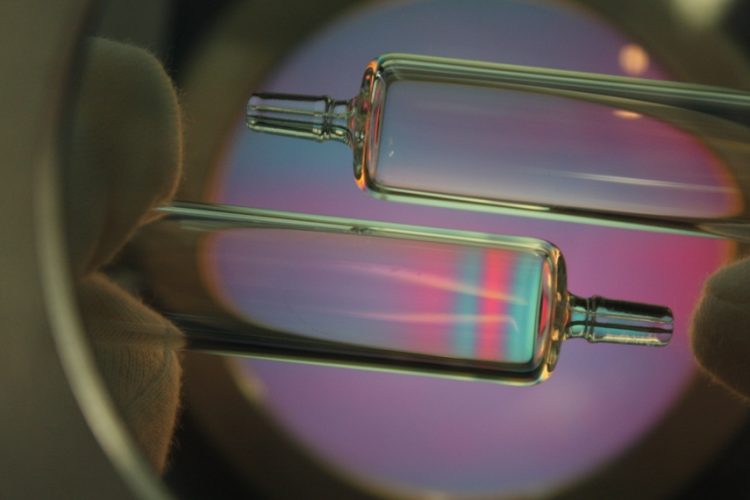

Did you know that tempering helps with the production of glass bottles and ampoules for the pharmaceutical industry?

The glass is formed under heat, which means there are residual thermal stresses and the glass is more likely to crack. For this reason, these thermal stresses must be removed before they are put into use. Stress relief is achieved by tempering.

Innovative MAX infrared ovens from Heraeus Noblelight support this process with convincing results.

Are you interested in the entire case story about glass tempering with the new MAX infrared oven?

Contact us here!

Industrial infrared heating oven

The MAX ovens combine infrared radiation with convection and optimal reflection. Only quartz glass materials including QRC® nano-reflectors are used inside the oven.

From simulation to solution

The oven size can be adjusted to the product and the process. Numerical simulation in the design phase makes the heat process especially energy-efficient. To achieve a maximum product temperature of 900°C, a MAX oven needs less than ten minutes, and it can cool down in less than ten minutes as well. This enables rapid product changes. The MAX oven can be used for both batch and continuous operation.

MAX oven – especially energy-efficient

Tests show that in an oven with a heated length of 700 mm and a chamber cross-section of 150 x 150 mm the maximal emitter temperature is achieved within less than one minute. In continuous operation at 900°C holding temperature, the necessary holding power is just about 3 kW, due to the excellent energy efficiency.

- High purity for sensitive products

- Thermal shock resistance for fast processes

- Best optical properties

- Excellent mechanical stability even at very high temperatures

- Very good processability for flexible oven dimensions

- Very good homogeneity of the temperature field due to diffuse reflection

Heraeus Noblelight GmbH

Heraeussstr. 12-14

D-63450 Hanau

Phone +49 6181 35 8547

Fax +49 6181 35 16 8547

E-Mail: hng-info@heraeus.com

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…