First Cellulose-based Micro- und Supermicro-Fibres Produced as Continuous Yarn for the Weaving and Knitting Technology

A novel direct-wet-spin process was developed and patented by the German Institute of Textile Chemistry and Chemical Fibres (ITCF) in Denkendorf, which allows for the first time the cost-efficient production of micro- and supermicro-fibres of less than 0.1-0.5 dtex (fibre surface about 1 – 4 m2/g) from cellulose and cellulose-2.5-acetate in the form of a continuous fibre in a single step process. The fibres can be stored as staple fibres or wound up as a continuous fibre for further processing.

Further Information: PDF

Technologie-Lizenz-Büro (TLB) der Baden-Württembergischen Hochschulen GmbH

Phone: +49 (0)721/79 00 40

Contact

Dipl.-Biol. Marcus Lehnen, MBA

Media Contact

All latest news from the category: Technology Offerings

Newest articles

Recovering phosphorus from sewage sludge ash

Chemical and heat treatment of sewage sludge can recover phosphorus in a process that could help address the problem of diminishing supplies of phosphorus ores. Valuable supplies of phosphorus could…

Efficient, sustainable and cost-effective hybrid energy storage system for modern power grids

EU project HyFlow: Over three years of research, the consortium of the EU project HyFlow has successfully developed a highly efficient, sustainable, and cost-effective hybrid energy storage system (HESS) that…

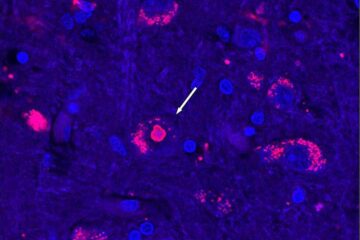

After 25 years, researchers uncover genetic cause of rare neurological disease

Some families call it a trial of faith. Others just call it a curse. The progressive neurological disease known as spinocerebellar ataxia 4 (SCA4) is a rare condition, but its…