Direct ReSi – Si-recovery from recycling of SiC-slurry

The production of Si-wafers for solar cells or semiconductors still utilizes wire saw cutting to turn silicon bricks into wafers. The actual cutting is performed by the cutting slurry, a suspension of silicon carbide (SiC) in cooling fluid. Recycling of the waste slurry, which contains silicon (Si) and SiC as valuable materials, can generate cost savings. The demand for Si-wafers, and therefore the need for cost-effective and efficient recycling continuously increases.

After separation of the coarse SiC-particles, the remaining mixture of Si and SiC is treated with acids. Si is concerted into Chlorosilane, and the remaining SiC recovered. The Chlorosilane can be feed into the production process for silicon.

Further Information: PDF

PROvendis GmbH

Phone: +49 (0)208/94105 10

Contact

Dipl.-Ing. Alfred Schillert

Media Contact

All latest news from the category: Technology Offerings

Newest articles

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

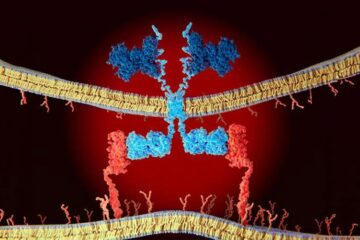

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…