Laser Technology Can Improve Hearing

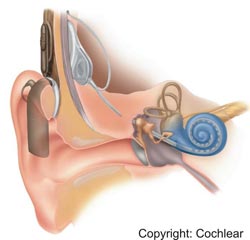

Cochlea implant with an external microphone and micro-speech-processor (illustration copyright: Cochlear)<br>

The Laser Zentrum Hannover e.V. (LZH) is developing innovative technologies for improved insertion techniques and exact fitting of cochlea implants in the inner ear, as well as better quality for residual hearing. Current results will be presented the the LZH Stand at the Hannover Messe 2012, from April 23rd to 27th.

Approximately 95% of all those who are highly hearing impaired have an adequately intact auditory nerve, enough to provide at least partial hearing. An important device for this process is a cochlea implant (CI), and electronical acoustic aid or prosthesis, which takes over the function of damaged sensory cells in the inner ear. This aid consists of an implant, which is placed in the bone, under the skin behind the ear, an electrode which is placed directly in the cochlea, and a microphone and speech processor, which is also placed behind the ear. The aid functions in this way: When sound waves are registered by the microphone, they are “translated” into a series of electrical impulses, which are then lead to the electrode on the auditory nerve in the inner ear.

The basilar membrane, which is covered by tiny sensory cells or hairs, can only provide optimal hearing if it is not damaged. If this membrane is damaged, this can lead to complete loss of residual hearing. This means that the cochlea electrode must be inserted extremely carefully, to avoid damage to the membrane.

The group “Surface Technology” at the LZH is currently working on a process to simplify the operation and improve the insertion technique of the electrode into the complicated form of the cochlea. In order to accomplish this, the scientists use the special properties of nickel-titanium shape memory alloys (NiTi-SMA) in manufacturing the CI electrodes.

By heating the electrode, or via electrical impulses, this material “remembers” the form or shape it was manufactured in, thus allowing specific movement and fitting of the electrode. On the one hand, laser melting is used to form the NiTi-SMA into a highly individual implant. On the other hand, the special characteristics of the material can be used to insert the implant into the cochlea without damaging the basilar membrane. Basically, the deeper the material is inserted into the cochlea and the better the fit, the better hearing can be.

At the Laser Zentrum Hannover, a second approach is also being used to optimize the characteristics of cochlea implants. The group Laser Micromachining has set a goal of improving the surface of implants by using laser structuring. “The surface of conventional cochlea implants is not subject to special treatment, and a great potential is lost! We have learned from mother nature that biological surfaces, for example of lotus leaves or shark skin, have defined structures for special functions” explains scientist Elena Fadeeva. By using a femtosecond laser, the platinum electrodes can be structured in a special way. Special nanostructures, looking very rough when magnified, can be manufactured, which reduce attachment of connective tissue and improve interaction with the nerve cells. Simultaneously, nanostructuring decreases frequency-dependent electrical resistance, meaning less energy is needed. The special challenge of this innovative development is that the structures must be made on an implant which is only 300 µm in diameter, and which has a curved surface. At the moment, the LZH is working on a unit, which can provide these complex structures on a very small scale.

Cochlea implants are especially interesting for people who, even with the best hearing aids, cannot understand spoken language well enough. Over 200,000 people worldwide could profit from these “artificial inner ears”. About half of the adults using CIs could even use the telephone again after sufficient training takes place. For those having shortly lost hearing, or for children, the success rate should be even higher.

Current activities at the LZH concerning cochlea implants are being financially supported within the framework of the German Federal Ministry of Education and Research (BMBF) project Gentle CI, and by the interdisciplinary special research program 599 of the German Research Foundation (DFG). Among the project partners is the Hannover Medical School (MHH), which has the world’s largest cochlea implant program for the extremely hearing impaired.

Be sure to visit us at the Hannover Messe 2012 (April 23rd to 27th), in hall 17, stand C55.

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover, Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Trade Fair News

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…