Increasing the Productivity of Ultrafast Laser Systems

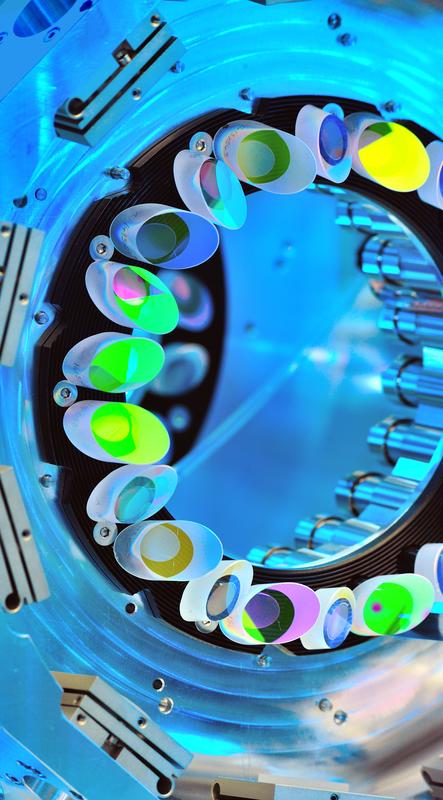

Thin Disc amplifier with 1.5 kW © Fraunhofer ILT, Aachen, Germany

At the last UKP-Workshop: Ultrafast Laser Technology in Aachen from Fraunhofer ILT in April 2015, the participants agreed that an increase in productivity is currently the most important issue in industrial ultrafast lasers. The increase depends on many parameters, for example, the pulse energy, repetition rate and process control. Shorter pulses allow for greater precision and completely new machining processes, e.g., by multiphoton absorption or filament formation in glass.

New Module to Shorten the Pulses of Ultrafast Lasers with Highest Average Power

Fraunhofer ILT has now developed an optical module that shortens the pulse duration of powerful ultrafast lasers by a factor of four. The compact module is suitable for use in lasers with up to 1 kW average power and energy from 10 to 200 µJ. A 1 ps pulse can thus be compressed to about 250 fs, during which less than 10 percent of energy is lost and the beam quality is maintained.

The patent-pending technology of the pulse-shortening module was funded by the Federal Ministry of Education and Research (BMBF) as part of the FOCUS project. In the further development of the module, significantly higher pulse energies are to be achieved.

The pulse-shortening module can be combined with a femtosecond laser in the power range of 150 W, which has been newly developed at Fraunhofer ILT. The module has been fine-tuned for robustness and economy thanks to its particularly simple design. In its power class, it is even superior to the significantly more powerful INNOSLAB laser. Both concepts are characterized by their almost diffraction-limited beam quality.

New Record: Femtosecond Laser with 1.5 kW

By combining Thin Disk and INNOSLAB amplifiers, Fraunhofer ILT has set a new record for ultrafast lasers: the system delivers 1.5 kW average power at a pulse duration of 710 fs. Further optimization specifically of the thin-disk amplifier system should enable power beyond the 2 kW limit. This development has been supported by the BMBF as part of the FOCUS Project, as well as by the TRUMPF Group.

Industrial laser systems in this power class are particularly suitable for the processing of large parts, for example, those made of carbon fiber reinforced plastic (CFRP).

Powerful USP system for the SWIR Range

New beam sources for the infrared range at wavelengths of 1.5 to 3.5 µm (SWIR) provide an example of ultrafast laser technology solutions by Fraunhofer ILT, tailored for specific applications. Many technically and economically interesting material classes have an extremely high absorption in SWIR, which makes a series of innovative applications possible. So far, however, there has been a lack of sufficiently powerful lasers in this range.

Scientists at Fraunhofer ILT have now developed a test system that delivers laser power even over 20 W at 1.6 to 3.0 µm. The pulse duration can be between 900 fs and 1.5 ns. They are currently working on power scaling to more than 50 W. The test system can be adapted to different drive lasers and, thus, provide a wide range of application parameters.

The new system allows users to make both feasibility studies and provides process-optimized beam parameters for production.

Fraunhofer ILT at the LASER World of Photonics in Munich, Germany

From 22 – 25 June 2015 experts from the Fraunhofer ILT will be showing, among others, the module for pulse shortening for ultrafast laser systems and the test system for adjustable infrared lasers with high power at the Fraunhofer joint stand A3.121.

The researchers will also be presenting the exhibits at the Fraunhofer media tour on Tuesday, June 23, 2015. It starts at 11:00 a.m. at Booth 341 in Hall B3 and ends at approximately 12:00 midday at Booth 121 in Hall A3, followed by a discussion and light refreshments.

Contact

Dr. Peter Rußbüldt

Group Manager Ultrafast Lasers

Telephone +49 241 8906-303

peter.russbueldt@ilt.fraunhofer.de

Dipl.-Phys. Thomas Sartorius

Ultrafast Lasers

Telephone +49 241 8906-615

thomas.sartorius@ilt.fraunhofer.de

Dr. Bernd Jungbluth

Group Manager Nonlinear Optics and Tunable Lasers

Telephone +49 241 8906-414

bernd.jungbluth@ilt.fraunhofer.de

Fraunhofer-Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…