Bio-based films suitable for industrial use

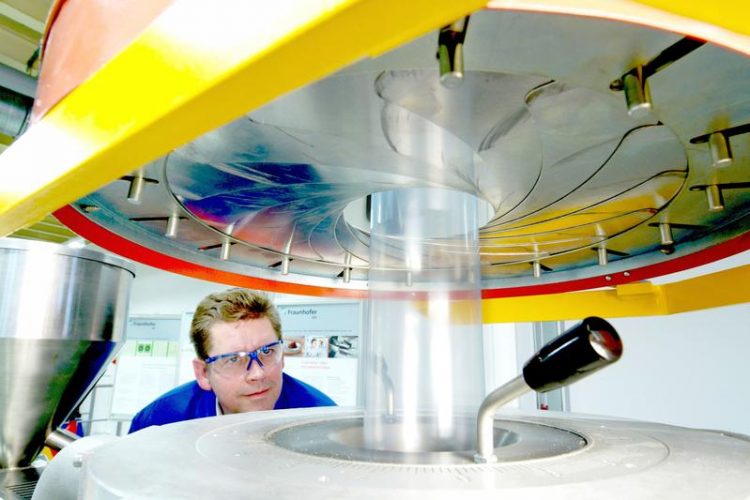

Bio-based blown film is produced at Fraunhofer IAP using common blown-film extrusion equipment. Fraunhofer IAP, photo: Till Budde

Films represent an important area of the plastics industry. The range of applications is diverse, from flexible films for the packaging sector, to bags and sacks, shrink-wrap and expanding films, films for agricultural and construction applications, films for office use and office supplies, insulating films, as well as other industrial film applications.

The characteristics and behavior of various biopolymers show great potential for these markets. The most well-known is a material named polylactic acid (PLA) along with the blends and compounds produced from it, though other more recent raw materials like polybutylene succinate (PBS) have come on the scene. However, biopolymer prices are quite high and their properties do not equal those of conventional petroleum-based polymers in all areas.

“In order to be able to utilize bioplastics for production of tubular or sheet film, the materials need to possess good processing properties and product characteristics. You also have to be sure that bioplastics can be processed by machinery available on the market just as well as common petroleum-based plastics can. We are researching both these areas at Fraunhofer IAP and have some very interesting new developments. We would like to share our experience and this knowledge with the workshop participants”, explains Dr. Mathias Hahn, a biopolymer expert at IAP.

Guest speakers from Mitsubishi Chemical Performance Polymers Corp Germany (MCPP) and Wacker Chemie AG will also be reporting on their experience and developments in the area of biomaterials including processing them in production. Moreover, opportunities for support of projects promoting the employment of biopolymers in plastics processing will be presented.

Last but not least, the event will promote the exchange of information and explore potential synergies as well. A tour of the Processing Pilot Plant for Biopolymers at Fraunhofer IAP in Schwarzheide will round out the program. Those interested in employing bioplastics for the production of film or those with general questions about bioplastics and how they are processed are invited to take part in this event.

The workshop is taking place as part of the Competence Network for the Processing of Biopolymers (KNVB) joint research project funded by the German Federal Ministry of Food and Agriculture (BMEL) through project sponsor FNR (Fachagentur Nachwachsende Rohstoffe e.V., an association dedicated to renewable resources).

Fraunhofer IAP conducts research in association with the Institute for Bioplastics and Biocomposites (IfBB) of the University of Applied Sciences and Arts Hanover, the German Plastics Center (SKZ) in Würzburg, and the Department of Lightweight Structures and Polymer Technology (SLK) at Technische Universität Chemnitz.

Information and contacts concerning the group research program “Verarbeitung von biobasierten Kunststoffen und Errichtung eines Kompetenznetzwerkes im Rahmen des Biopolymernetzwerkes der FNR“ can be found in the FNR project database at www.fnr.de by displaying the „Projekte & Förderung“ menu, clicking below on „Projekte“ / „Suche“ and entering program numbers 22017911, 22022512, 22022612, and 22022712.

Media Contact

More Information:

http://www.iap.fraunhofer.deAll latest news from the category: Seminars Workshops

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…