X-ray vision reveals how polymer solar cells wear out

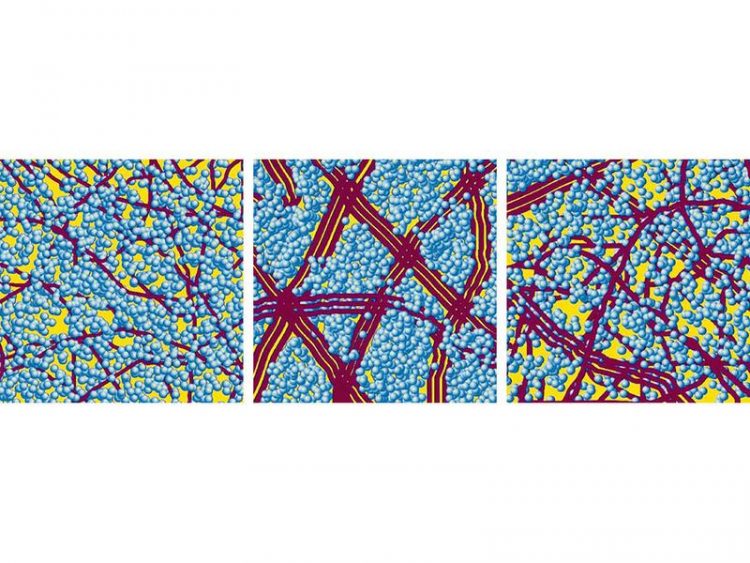

The inner structure of the solar cell’s active layer without (left), with (centre) and after loss of solvent additive (right). Image: Christoph Schaffer / TUM

Unlike conventional solar cells, which are made of silicon, organic solar cells produce electricity in an active blended layer between two carbon-based materials. When one of these is a polymer, the resulting cell is often referred to as a polymer solar cell. These are particularly promising because they can be manufactured simply and cheaply.

They can be used to make extremely lightweight, flexible and even semi-transparent solar cells using printing techniques on flexible polymer materials, opening up completely new fields of application. In general, however, organic solar cells are less efficient than silicon-based ones, and sometimes they have also a reduced lifetime.

Important inner values

The internal structure of the active layer is crucial in organic solar cells. When manufacturing them, the two materials that form the active layer have to separate out of a common solution, much like droplets of oil forming in water.

“It is important that the polymer domains formed in the process are a few tens of nanometres apart,” points out Christoph Schaffer, a PhD student in the Prof. Müller-Buschbaum, Chair for Functional Materials at TU Munich. “Only then positive and negative charge carriers can be efficiently produced in the active layer and separated from each other. If the structure is too coarse or too fine, this no longer happens, and the efficiency of the solar cell will decrease.”

Modern polymer solar cells often consist of so-called low-bandgap polymers, which absorb particularly large amounts of light. In many cases, these require the use of a solvent additive during the manufacturing process in order to achieve high efficiencies. However, this additive is controversial because it might further decrease the lifetime of the solar cells.

X-ray view into the solar cell

The scientists used DESY’s x-ray source PETRA III to study the degradation of such low-bandgap polymer solar cells with solvent additives in more detail. To this end, a solar cell of this type was exposed to simulated sunlight in a chamber, while its key parameters were continuously monitored.

Parallely, the scientists shone a narrowly collimated x-ray beam from PETRA III at the solar cell at different times, providing a picture of the internal structure of the active layer on a nanometre scale every few minutes.

“These measurements can be used to relate the structure to the performance of the solar cell and track it over time,” explains co-author Prof. Stephan Roth, who is in charge of DESY’s P03 beamline, where the experiments were conducted.

“The data reveals that domains that are on the scale of a few tens of nanometres shrink substantially during operation and that their geometric boundaries with other components disappear,” says Schaffer. At the same time, the measurements suggest that the amount of residual solvent additive decreases. The scientists attribute the measured drop in the efficiency of the solar cell to the observed decrease.

“Since there is evidence to suggest that the residual amount of solvent additive decreases, we have to assume that this process can limit the lifetime of the solar cells,” explains Müller-Buschbaum. “Therefore it is essential to come up with strategies for stabilising the structure. This could be achieved through chemical bonding between the polymer chains, or using customised encapsulating substances.”

Size is critical

In an earlier study, the Munich researchers observed the degradation of a different type of polymer solar cell. In that case, the efficiency was found to drop as a result of the active centres gradually growing in size during their operation. This suggested that it is in fact better to manufacture such solar cells with a suboptimal structure, i.e. one that is too fine, so that it can then grow to the optimum size during the first hours of operation.

The current study picks up the story where the previous one left off. “Our first study showed us that the efficiency dropped when the structure became coarser,” says Schaffer. “Exactly the opposite happens in the present study. This behaviour is precisely what we expected, because the composition of the active layer is different.”

“The materials in the first study tend to demix to a high degree,” explains Schaffer. “Here, the opposite is true, and we need the solvent additive in order to achieve the demixing of the materials that is needed to obtain high efficiencies. When the solvent additive disappears during operation, the structure becomes finer and therefore moves away from its optimum.”

Both these studies offer important approaches to optimising the manufacturing of organic solar cells, as co-author Roth points out: “The way these two studies fit together provides a wonderful example of how important synchrotron radiation has become, especially in applied research such as in the field of renewable energies.”

Publication:

Morphological Degradation in Low Bandgap Polymer Solar Cells – An In Operando Study; Christoph J. Schaffer, Claudia M. Palumbiny, Martin A. Niedermeier, Christian Burger, Gonzalo Santoro, Stephan V. Roth, and Peter Müller-Buschbaum

Advanced Energy Materials, 12.10.2016 – DOI: 10.1002/aenm.201600712

Contact:

Prof. Dr. Peter Müller-Buschbaum

Technical University of Munich

Department of Physics, E13

Chair for Functional Materials

James-Franck-Str. 1, 85748 Garching, Germany

Tel.: +49 89 289 12451 – E-mail: muellerb@ph.tum.de

http://www.functmat.ph.tum.de/

https://www.tum.de/en/about-tum/news/press-releases/short/article/33448/

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…