Researchers Devise New, Stretchable Antenna for Wearable Health Monitoring

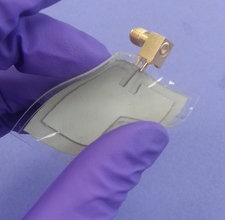

The extremely flexible antennas contain silver nanowires and can be incorporated into wearable health monitoring devices. Photo: Amanda Myers

“Many researchers – including our lab – have developed prototype sensors for wearable health systems, but there was a clear need to develop antennas that can be easily incorporated into those systems to transmit data from the sensors, so that patients can be monitored or diagnosed,” says Dr. Yong Zhu, an associate professor of mechanical and aerospace engineering at NC State and senior author of a paper describing the work.

The researchers wanted to develop an antenna that could be stretched, rolled or twisted and always return to its original shape, because wearable systems can be subject to a variety of stresses as patients move around.

To create an appropriately resilient, effective antenna, the researchers used a stencil to apply silver nanowires in a specific pattern and then poured a liquid polymer over the nanowires. When the polymer sets, it forms an elastic composite material that has the nanowires embedded in the desired pattern.

This patterned material forms the radiating element of a microstrip patch antenna. By manipulating the shape and dimensions of the radiating element, the researchers can control the frequency at which the antenna sends and receives signals. The radiating layer is then bonded to a “ground” layer, which is made of the same composite, except it has a continuous layer of silver nanowires embedded.

The researchers also learned that, while the antenna’s frequency does change as it is stretched (since that changes its dimensions), the frequency stays within a defined bandwidth. “This means it will still communicate effectively with remote equipment while being stretched,” Adams says. “In addition, it returns to its original shape and continues to work even after it has been significantly deformed, bent, twisted or rolled.” As the frequency changes almost linearly with the strain, the antenna can be used a wireless strain sensor as well.

“Other researchers have developed stretchable sensors, using liquid metal, for example,” Zhu says. “Our technique is relatively simple, can be integrated directly into the sensors themselves, and would be fairly easy to scale up.”

The work on the new, stretchable antenna builds on previous research from Zhu’s lab to create elastic conductors and multifunctional sensors using silver nanowires.

The paper, “Stretchable and Reversibly Deformable Radio Frequency Antennas Based on Silver Nanowires,” is published online in ACS Applied Materials & Interfaces. Lead author of the paper is Lingnan Song, an undergraduate at Zhejiang University who worked on the project at NC State during an exchange program. Co-authors include Amanda Myers, a Ph.D. student at NC State; and Dr. Jacob Adams, an assistant professor of electrical and computer engineering at NC State.

The work was supported in part by the National Science Foundation under grant EFRI-1240438 and by NSF’s ASSIST Engineering Research Center at NC State under grant EEC-1160483.

-shipman-

Note to Editors: The study abstract follows.

“Stretchable and Reversibly Deformable Radio Frequency Antennas Based on Silver Nanowires”

Authors: Lingnan Song, Amanda C. Myers, Jacob J. Adams, and Yong Zhu, North Carolina State University

Published: Online March 2014, ACS Applied Materials & Interfaces

DOI: 10.1021/am405972e

Abstract: We demonstrate a class of microstrip patch antennas that are stretchable, mechanically tunable and reversibly deformable. The radiating element of the antenna consists of highly conductive and stretchable material with screen-printed silver nanowires embedded in the surface layer of an elastomeric substrate. A 3-GHz microstrip patch antenna and a 6-GHz 2-element patch array are fabricated. Radiating properties of the antennas are characterized under tensile strain and agree well with the simulation results. The antenna is reconfigurable because the resonant frequency is a function of the applied tensile strain. The antenna is thus well suited for applications like wireless strain sensing. The material and fabrication technique reported here could be extended to achieve other types of stretchable antennas with more complex patterns and multi-layer structures.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…