Technology could use moon dust to capture sun power

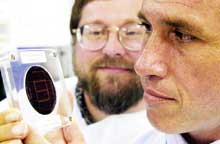

Alex Freundlich, right, research physics professor, and Charles Horton, senior research scientist at the Texas Center for Superconductivity and Advanced Materials at the University of Houston, have developed a high-efficiency, nano-engineered solar cell

UH Solar Cell Research Has Applications for Space Exploration, Clean Cars

New technologies designed to harness the power of the sun may hold the key to successful moon colonies, cheaper and lighter-weight satellites, and cleaner-burning, more efficient car engines.

Solar cells, electronic devices that convert sunlight into useful electricity, would be an important resource for powering future industrial bases or colonies on the moon. Alex Freundlich, research professor of physics, and Charles Horton, senior research scientist at the Texas Center for Superconductivity and Advanced Materials at UH, or TcSAM, are developing methods to manufacture huge solar cell arrays on the moon using materials from the lunar soil.

“The raw materials needed to make solar cells are present in the moon’s regolith,” says Freundlich, who has examined lunar material to determine whether it contains the necessary ingredients for making solar cells. He, Horton, Alex Ignatiev, director of TcSAM, and a team of NASA-JSC and industry scientists also have used “simulated” moon soil to determine how to go about manufacturing the solar cell devices on the moon.

The UH scientists will present talks on three solar cell research projects during the World Space Congress 2002 Oct. 10-19 in Houston.

“Our plan is to use an autonomous lunar rover to move across the moon’s surface, to melt the regolith into a very thin film of glass and then to deposit thin film solar cells on that lunar glass substrate. An array of such lunar solar cells could then be used as a giant solar energy converter generating electricity,” Freundlich says. “These solar cells would have lower efficiencies compared to devices currently used on Earth, but by using such a large surface area, we could eventually generate enough electricity to supply a lunar base, support lunar manufacturing or colonies.”

Another possible use for a lunar solar power system would be to generate electricity to beam back to the Earth for use in local electric grids. UH physicist David Criswell has spent 20 years developing such a plan.

Freundlich and Horton also are developing solar cells that are more efficient at converting sunlight to electricity than those currently used to power orbiting satellites. The materials used in their advanced solar cells, and the way those materials are configured, also make them more resistant to the damaging effects of radiation.

“The best space solar cell technology currently in use converts only about 28 percent of the sunlight hitting the device into electricity,” Freundlich says. “By adding a thin layer of nano-engineered material in these cells we are capable of boosting solar cell efficiencies to well above 35 percent. These cells potentially would last much longer because they are much more resistant to being degraded by radiation from the sun and space.”

One of the most radiation-laden areas surrounding the Earth, the Van Allen Belts, would be an optimal place to put orbiting telecommunications satellites, Horton says. Unfortunately, it’s the worst environment for a satellite. The radiation there can be 100 times stronger than that found in geosynchronous orbit, where most satellites operate.

“It takes less fuel to launch a satellite into the Van Allen Belt region since that area is not as far away as geosynchronous orbit, so satellites in that closer orbit would improve on the time it takes signals to be transmitted around the world,” Horton says. “Using our radiation-hard technology, satellites could be used closer to the Van Allen Belt. Also, if this technology were to be used in geosynchronous satellites, they still would operate at higher efficiency over a longer period of time that what’s up there now.”

Freundlich and Horton also are working on a variation of solar cell technology, called thermophotovoltaics, or TPVs, which directly convert heat into electricity. While the concept is not new, the UH researchers say there is a “renewed interest in an older field.” As an example, the technology could be used to power deep space exploration spacecraft in conjunction with a radioactive source to generate the necessary heat.

The UH scientists are using nanotechnology to change the structure of existing TPV materials in a way that extends the amount of infrared radiation the device can convert to electricity. This modification allows the UH materials to operate at much higher efficiencies and lower temperatures than existing TPV technologies.

Because the UH TPVs are much more efficient than those currently used in the space program, the technology may increase the longevity and range of deep-space missions, Horton says.

“The temperature of the heat source for our material needs to be about 900 to 1000 degrees Celsius to generate useful electricity. It doesn’t matter what the source of the heat is,” Horton says. “Using this technology to capture the heat generated at the heart of the coals in your barbeque grill, at about 800 to 900 degrees, you could generate enough electricity to run kitchen appliances. These devices could operate using the excess heat produced by boilers in power plants, for example. The energy that is currently wasted could be recuperated.”

The UH innovations in TPVs also could be used to create cleaner-burning car engines.

“A car utilizing this technology would still burn gasoline, but would be powered by TPV-generated electricity,” Freundlich says. “Because the gasoline would burn and not explode as in a conventional engine, the gasoline would burn more efficiently and burn completely, thus producing much less harmful emissions. Such a car would use less gas, and you can still use gas stations.”

Also, because the TPVs absorb the infrared radiation from the engine, the vehicle would be invisible to night vision, which could be important for military operations, Freundlich says.

NASA, the state of Texas and private industry have funded Horton’s and Freundlich’s research.

About the University of Houston

The University of Houston, Texas’ premier metropolitan research and teaching institution, is home to more than 40 research centers and institutes and sponsors more than 300 partnerships with corporate, civic and governmental entities. UH, the most diverse research university in the country, stands at the forefront of education, research and service with more than 34,400 students.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…