Advanced Simulation Tools to Fight Microchip Variations

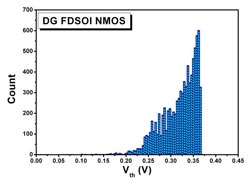

Simulation example for distribution of switching voltage of an advanced CMOS transistor due to focus variations in optical lithography<br><br>Fraunhofer

Process, device, and circuit simulation tools are essential in reducing time to market and the cost of new microchip technology development, delivering faster computers, better consumer products and fueling the digital economy.

The International Technology Roadmap for Semiconductors (ITRS) estimates that the use of such tools reduces chip development times and costs by about 40%. Advanced semiconductor devices and circuits are increasingly affected by different kinds of variations which occur during the process of chip fabrication.

Within the European project SUPERTHEME, a tool chain for the simulation of the impact of process variations on the devices, circuits and systems fabricated will be developed. This will allow the global semiconductor industry to minimize the detrimental effects of such variations on chips used e.g. in computers, tablets and mobile phones.

CMOS process variability includes both systematic variations caused by equipment settings and inhomogeneities which cannot be controlled with sufficient accuracy, and statistical variations which are for instance caused by the discreteness of charge and the granularity of matter in nanometer scale transistors. Effects from various sources of process variations, both systematic and stochastic, influence each other and lead to variations of the electrical, thermal and mechanical behavior of devices, interconnects and circuits. This presents a major challenge for the continued scaling of transistor dimensions and the increase in the com-plexity and functionality of computer chips which are essential for the economic success of the semiconductor industry.

Correlations between different effects of variability are of key importance because they drastically affect the production yield and the performance of chips and corresponding consumer products. Whereas the comprehensive experimental investigation of these effects is largely impossible, suitable simulation tools offer the possibility to pre-dict the effect of process variations on subsequent process steps and on the behavior of final fabricated devices and circuits. This important application of simulation is among others high-lighted in the ITRS.

The SUPERTHEME consortium will address and remove the most problematic weaknesses which limit the use of current simulation software to study the influence of both systematic and stochastic process variability and its interaction with electro-thermo-mechanical effects. Particular emphasis will be put on the study of correlations as their treatment needs to be an essential feature of the simulation system. The project will efficiently combine the use of commercially available software and leading-edge background results of the consortium partners with the research, development and implementation of the key missing elements bridging the current critical gap between variability simulation at the process and device/interconnect level. The capabilities of the software system will be demonstrated both on advanced analog circuits and on aggressively scaled digital CMOS technologies.

To reach these ambitious goals, a consortium of European companies active in complementary fields and leading European research institutes and Universities has been formed, which covers a wide range of expertise from semiconductor equipment and technology to modelling and simulation, and finally industrial exploitation.

On October 2, 2012, the project coordinator, the Fraunhofer IISB in Erlangen, Germany, hosted the kickoff meeting for the 3-year project, which has a total budget of 4.79 million Euros.

SUPERTHEME is funded by the European Union in the 7th Framework Programme, under the ICT project number 318458.

Project participants:

– Coordinator: Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. (Germany)

– ams AG (Austria)

– Gold Standard Simulations ltd (United Kingdom)

– University of Glasgow (United Kingdom)

– Technische Universität Wien (Austria)

– ASML Netherlands B.V. (Netherlands)

– Excico France (France)

– HQ-Dielectrics GmbH (Germany)

– IBS (France)

Contact

Dr. Jürgen Lorenz

Fraunhofer IISB

Schottkystrasse 10, 91058 Erlangen, Germany

Tel. +49-9131-761-210

Fax +49-9131-761-212

juergen.lorenz@iisb.fraunhofer.de

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…