20.1%-efficient screen printed silicon solar cell with novel rear passivation layer

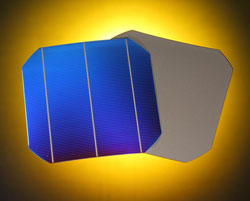

Prototype of the screen-printed solar cell with 20.1% efficiendy andd ICP-ALOx/SiNy-passivation layer. Photo: ISFH (Salzmann PhotoDesign)<br>

A novel ICP-AlOx / SiNy double layer at the rear side of the solar cell enables the improvement without applying a “selective emitter”. 20.1% is one of the highest efficiencies worldwide reported for industrial type silicon solar cells with screen-printed metallization (only Schott Solar and Q-Cells achieved higher efficiencies of 20.2%).

Two technological improvements enable the increased conversion efficiency. First, an ICP-AlOx/SiNy double layer passivates the rear surface of the solar cell. ICP stands for “Inductively Coupled Plasma”, which is a novel deposition method for AlOx developed at ISFH in cooperation with SINGULUS TECHNOLOGIES AG. SINGULUS is currently developing an integrated production solution for this passivation layer stack. The screen-printed aluminum on the cell’s rear side locally contacts the silicon wafer through line shaped contact openings formed by laser ablation. The modified cell rear improves reflection and reduces the charge carrier recombination which increases both the current and voltage of the solar cell.

Second, the cell front side is metallized using a “Print on Print” process, which results in a reduced contact finger width and hence less shadowing loss. This advanced screen printing process was optimized at ISFH in collaboration with DEK Solar, using their high accuracy Eclipse screen printing platform and precision screens. Beyond these innovations, the solar cell applies typical industrial processes, in particular a homogeneously phosphorus diffused emitter and a 156 x 156 mm2 large Czochralski (Cz) silicon wafer.

“This excellent result was achieved within the research project HighScreen funded by the German Federal Ministry of the Environment and also funded by our partners SolarWorld AG, Schott Solar AG, Solland Solar Cells GmbH, RENA GmbH und SINGULUS TECHNOLOGIES AG”, explains Dr. Thorsten Dullweber, head of the ISFH research group Solar Cell Production Processes. “Additionally, our collaboration with DEK Solar, Ferro Corporation and Heraeus GmbH accelerated the progress.” Prof. Dr. Rolf Brendel, Director of the ISFH, adds: “These technological innovations show the high potential to further reduce the costs of photovoltaic electricity.”

“The significant efficiency improvement demonstrated by the ICP-AlOx process further encourages SINGULUS in our strategy to offer an integrated production solution with ICP-AlOx for rear passivated solar cells”, explains Dr. Björn Roos, Product Manager Solar at SINGULUS TECHNOLOGIES AG.

About 80% of today’s industrially manufactured solar cells apply p-type silicon wafers in combination with screen printed metal contacts. Hence, efficiency improvements for this type of solar cell are highly relevant for the photovoltaic industry and represent an intensive field of research worldwide.

Media Contact

More Information:

http://www.isfh.de/All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…