Rice engineers make first pure nanotube fibers

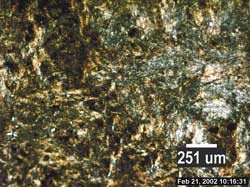

This image shows a liquid crystalline solution of sulfuric acid and SWNTs. The solution contains roughly 5.5 percent SWNTs by volume; acid dispersions have resulted in over an order of magnitude improvement in concentration over all previously documented methods.

Discovery could allow industrial production of cables, sheets of pure carbon nanotubes

Researchers at Rice University have discovered how to create continuous fibers of out of pristine single-walled carbon nanotubes. The process, which is similar to the one used to make Kevlar® on an industrial scale, offers the first real hope of making threads, cables and sheets of pure carbon nanotubes (SWNTs).

The research is available online today from the journal Macromolecules.

Scientists estimate nanotubes are about 100 times stronger than steel at one-sixth the weight. By comparison, Kevlar® — the fiber used in bulletproof body armor — is about five times stronger than an equal weight of steel. So far, no large-scale objects have been made of pure nanotubes due to a lack of processing methods that are viable on an industrial scale.

Rice’s team believes they have overcome the major hurdle to industrial production of macroscale SWNT objects — finding a way to store large amounts of nanotubes in liquid form. By dissolving nanotubes in strong sulfuric acid, a team of chemists and chemical engineers was able to achieve solutions containing up to 10 percent by weight of pure carbon

nanotubes — more than 10 times the highest concentrations

previously achieved. This new processing route uses no polymeric

additives or detergents, which were used in previous processing

methods and are known to be an obstacle to commercial scalability and final product purity.

“As the concentration increases, the nanotubes first align themselves into spaghetti-like strands and eventually they form tightly packed liquid crystals that can be processed into pure fibers,” said researcher Matteo Pasquali, assistant professor of chemical engineering.

Nanotubes are hollow cylinders of pure carbon that are just one atom thick. In addition to being very strong, nanotubes can also be either metals or semi-conductors, which means they could be used to manufacture materials that are both “smart” and ultrastrong. NASA, for example, is researching how nanotubes could be use in aircraft and spacecraft.

Chemically, carbon nanotubes are difficult to work with. They are strongly attracted to one another and tend to stick together in hairball-like clumps. Scientists have developed ways to untangle and sort nanotubes, but storing them after processing is difficult. To date, the medium of choice has been detergent and water solutions that contain less than 1 percent of dispersed nanotubes by volume and are processed by using polymer solutions. Such concentrations are too low to support industrial processes aimed at making large nanotube fibers. Moreover, scientists haven’t found a way to remove all the soap and polymer and convert the nanotubes back into their pure form.

“To produce large objects out of nanotubes, chemical processes must use a liquid that can disperse large concentrations of pristine tubes,” said Pasquali. “Based on our findings, we believe superacids can be used to make macroscale fibers and sheets of nanotubes using methods that are quite similar to those in widespread use by the chemical industry.”

The research paper is titled “Phase Behavior and Rheology of SWNTs in Superacids.” Pasquali’s co-authors include Richard E. Smalley, University Professor, the Gene and Norman Hackerman Professor of Chemistry and professor of physics; Robert H. Hauge, distinguished faculty fellow; W. Wade Adams, director, Center for Nanoscale Science and Technology; W.E. Billups, professor of chemistry; research scientists Carter Kittrell, S. Ramesh, and Rajesh K. Saini; graduate students Virginia A. Davis, Lars M. Ericson, A. Nicholas G. Parra-Vasquez, Hua Fan, and Yuhuang Wang, and undergraduate students Valentin Prieto and Jason A. Longoria.

###

This research was funded by the Office of Naval Research, NASA, the Robert A. Welch Foundation and the Nanoscale Science and Engineering Initiative of the National Science Foundation.

The paper is available online at:

http://pubs3.acs.org/acs/journals/toc.page?incoden=mamobx&indecade=0&involume=0&inissue=0.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…