Malaysian researchers create new durable wood-plastic composite material

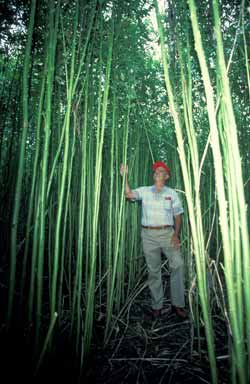

Kenaf (Hibiscus cannabinus), is a plant in the Malvaceae family. Kenaf is cultivated for its fibre in India, Bangladesh, United States of America, Indonesia, Malaysia, South Africa, Viet Nam, Thailand, parts of Africa, and to a small extent in southeast Europe.<br>

Wood-plastic composites (WPCs) are one of the fastest growing construction components in the wood composites industry. Their popularity is due to low maintenance, high durability, and resistance to termites and other insect attacks. However their widespread usage has been limited due to their high cost in production and in some instances low strength.

The present study focused on assessing the suitability of kenaf core fraction (about 65%of the whole stem of the plant) in powder form as filler material. Kenaf powder, processed from its core fibre, has been shown to offer one potential solution to the increasing scarcity of traditional filler materials. Kenaf stems contain two distinct fibre types, bast and core. Dosing with maleic-anhydride-modified polypropylene (MAPP) in the right amount displayed not only to bridge the interface between the ground kenaf core (GKC) and plastic in the present WPCs, improving stress transfer and increasing their strength and stiffness, but also allow a higher filler loading. Reducing the amount of plastic and increasing the amount of GKC, without sacrificing strength, stiffness or durability, would result in greener WPC products.

Researchers examined the possibility of replacing sawdust with GKC and measured the mechanical properties of the resulting composites. They also looked at the effect of increasing maleic-anhydride-modified polypropylene (MAPP) dosage. Material preparation included GKC drying followed by high intensity blending with polypropylene (PP), coupling agents (MAPP) pellets, and feeding this into a counter-rotating twin-screw extruder for compounding. Compounded blends were then fed to an injection-moulding machine to produce boards of dimensions 153mm x 153mm x 3mm. Specimens were cut from the boards for tensile and bending tests in five replicates. GKC formulation gave the highest average tensile strength, modulus of rupture and modulus of elasticity.

WPCs of polypropylene (PP) and ground kenaf core (GKC) fibre, dosed with maleic-anhydride-modified polypropylene (MAPP) in the right amount, was found not only to bridge the interface between the GKC and plastic, improving stress transfer and increasing their strength and stiffness, but also allow a higher filler loading of 65%. Reducing the amount of plastic and increasing the amount of GKC, without sacrificing strength, stiffness or durability, would result in greener WPC products. The researchers recommend that additional testing and extended research is necessary to investigate the strength of WPC on mechanical properties of modulus of elasticity (MOE) and modulus of rupture (MOR) by carrying out impact test and compressive test which could reveal new discoveries about high filler loading WPCs.

ARUAN EFENDY MOHD GHAZALI

aruan624@salam.uitm.edu.my

Ir. SHAHARIN HAMID

Ir. ABDUL HALIM ABDUL GHANI

Funding information

Excellence Fund, Research Management Institute (RMI) University Teknologi MARA, Malaysia.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…