Suppliers Benefit from Sustainability

The magazine Pictures of the Future reports that the company is gradually expanding its energy efficiency program to also include the supplier chain. The EEP for Suppliers (EEP4S) program identifies and evaluates energy-saving potential in production processes and can reduce energy consumption by as much as 17 percent.

One of the first participants in the program was a foundry that supplies Siemens with cast steel used in the production of steam turbines. Just a single suggestion from Siemens consultants has ended up saving the foundry €14,000 per year, enabling the supplier to recoup half of its energy-conservation investment in the first year.

Siemens has been examining and evaluating energy-saving potential at its own facilities since 2006, and more than 100 of the Group’s 300 plants have already undergone the Siemens Energy Health Check. Electricity consumption at the production facilities declined by 11 percent on average between 2006 and 2010 as a result.

Supplier sustainability is also important, however, because Siemens is one of the world’s biggest procurers of products and services: In 2010 the Group made purchases totaling approximately €37 billion in 177 countries. EEP for Suppliers was therefore launched to reduce energy consumption in the supplier chain. Participants can choose between four program variants designed in accordance with the energy intensity of their production processes and their level of production volume. Participants that opt for the most extensive variant are visited for several days by certified Siemens environmental consultants who tour the entire factory, analyze building structures, closely examine the energy consumption of individual units, study manufacturing and maintenance processes, and review procurement contracts.

The consultants then draw up a report in which they present proposals for energy-saving measures, calculate the required investment, and estimate how long it will take for the energy savings to pay for the outlay. The supplier pays the consulting costs. Also available is a free self-assessment tool that allows small companies or plants with less energy-intensive operations to assess their processes and identify savings potential.

Siemens incorporated an initial 160 suppliers with energy-intensive production processes into the EEP4S program in business year 2010 – 2011. A further 840 companies will be added next year. Plans call for EEP4S to become an established part of the Siemens supplier management system over the long term.

Media Contact

More Information:

http://www.siemens.com/innovationnewsAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Recovering phosphorus from sewage sludge ash

Chemical and heat treatment of sewage sludge can recover phosphorus in a process that could help address the problem of diminishing supplies of phosphorus ores. Valuable supplies of phosphorus could…

Efficient, sustainable and cost-effective hybrid energy storage system for modern power grids

EU project HyFlow: Over three years of research, the consortium of the EU project HyFlow has successfully developed a highly efficient, sustainable, and cost-effective hybrid energy storage system (HESS) that…

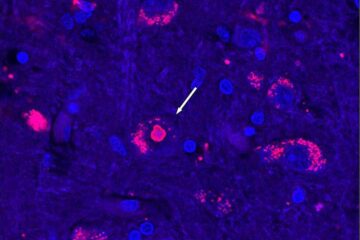

After 25 years, researchers uncover genetic cause of rare neurological disease

Some families call it a trial of faith. Others just call it a curse. The progressive neurological disease known as spinocerebellar ataxia 4 (SCA4) is a rare condition, but its…