Milestone: Miniature particle accelerator works

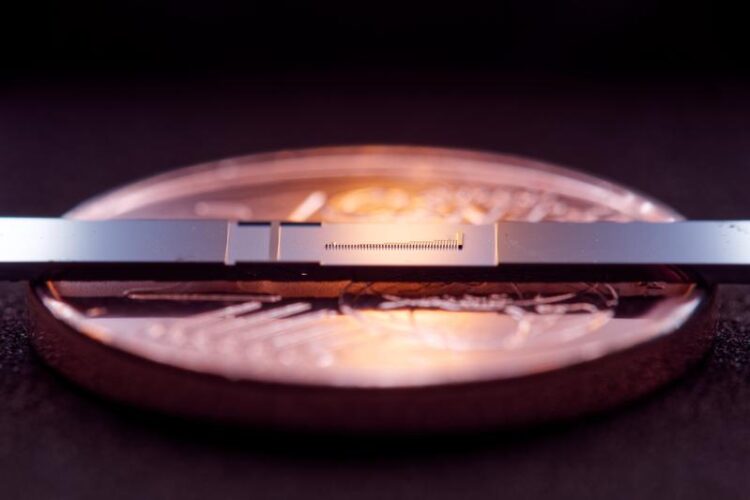

For the first time, FAU researchers have succeeded in measurably accelerating electrons in structures that are only a few nanometers in size. In the picture you can see the microchip with the structures and, in comparison, a 1 cent coin.

Image: FAU/Julian Litzel

FAU team of researchers succeed for the first time in accelerating electrons using a nano device.

Particle accelerators are crucial tools in a wide variety of areas in industry, research and the medical sector. The space these machines require ranges from a few square meters to large research centers. Using lasers to accelerate electrons within a photonic nanostructure constitutes a microscopic alternative with the potential of generating significantly lower costs and making devices considerably less bulky. Until now, no substantial energy gains were demonstrated. In other words, it has not been shown that electrons really have increased in speed significantly. A team of laser physicists at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) has now succeeded in demonstrating the first nanophotonic electron accelerator – at the same time as colleagues from Stanford University. The researchers from FAU have now published their findings in the journal “Nature”.*

When people hear “particle accelerator”, most will probably think of the Large Hadron Collider in Geneva, the approximately 27 kilometer long ring-shaped tunnel which researchers from around the globe used to conduct research into unknown elementary particles. Such huge particle accelerators are the exception, however. We are more likely to encounter them in other places in our day to day lives, for example in medical imaging procedures or during radiation to treat tumors. Even then, however, the devices are several meters in size and still rather bulky, with room for improvement in terms of performance. In a bid to improve and decrease the size of existing devices, physicists around the globe are working on dielectric laser acceleration, also known as nanophotonic accelerators. The structures they use are merely 0.5 millimeters in length, and the channel the electrons are accelerated through is only roughly 225 nanometers in width, making these accelerators as small as a computer chip.

Particles are accelerated by ultrashort laser pulses illuminating the nano-structures. “The dream application would be to place a particle accelerator on an endoscope in order to be able to administer radiotherapy directly at the affected area within the body,” explains Dr. Tomáš Chlouba, one of the four lead authors of the recently published paper. This dream may still be far beyond the grasp of the FAU team from the Chair of Laser Physics led by Prof. Dr. Peter Hommelhoff and consisting of Dr. Tomáš Chlouba, Dr. Roy Shiloh, Stefanie Kraus, Leon Brückner and Julian Litzel, but they have now succeeded in taking a decisive step in the right direction by demonstrating the nanophotonic electron accelerator. “For the first time, we really can speak about a particle accelerator on a chip,” enthuses Dr. Roy Shiloh.

Guiding electrons + acceleration = particle accelerator

Just over two years ago the team made their first major breakthrough: they succeeded in using the alternating phase focusing (APF) method from the early days of acceleration theory to control the flow of electrons in a vacuum channel over long distances (see press release of September 23, 2021: https://www.fau.eu/2021/09/23/news/research/fau-physicists-control-the-flow-of-e…). This was the first major step on the way towards building a particle accelerator. Now, all that was needed to gain major amounts of energy was acceleration. “Using this technique, we have now succeeded not only in guiding electrons but also in accelerating them in these nano-fabricated structures over a length of half a millimeter,” explains Stefanie Kraus. Whilst this might not sound like much of an achievement to many, it is a huge success for the field of accelerator physics. “We gained energy of 12 kiloelectron volts. That is a 43 percent gain in energy,” explains Leon Brückner.

In order to accelerate the particles over such large distances (when seen from the nano scale), the FAU physicists combined the APF method with specially developed pillar-shaped geometrical structures.

This demonstration is just the beginning, however. Now the aim is to increase the gain in energy and electron current to such an extent that the particle accelerator on a chip is sufficient for applications in medicine. For this to be the case, the gain in energy would have to be increased by a factor of approximately 100. “In order to achieve higher electron currents at higher energies at the output of the structure, we will have to expand the structures or place several channels next to each other,” Tomáš Chlouba explains the next steps of the FAU laser physicists.

Head-to-head race among physicists

What the Erlangen laser physicists succeeded in doing was demonstrated almost simultaneously by colleagues at Stanford University in the United States: Their results are currently under review, but can be viewed on a repository. The two teams are working together on the realization of the “Accelerator on a chip” in a project funded by the Gordon and Betty Moore Foundation (https://www.fau.eu/2015/11/19/news/research/a-mini-particle-accelerator/). “In 2015, the FAU and Stanford led ACHIP team had a vision for a revolutionary approach to particle accelerator design”, said Dr. Gary Greenburg of the Gordon and Betty Moore Foundation, “and we are delighted that our support has helped turn this vision into reality.”

* Original FAU publication: T. Chlouba, R. Shiloh, S. Kraus, L. Brückner, J. Litzel and P. Hommelhoff, https://www.nature.com/articles/s41586-023-06602-7

Original Stanford publication: P. Broaddus, T. Egenolf, D. S. Black, M. Murillo, C. Woodahl, Yu Miao, U. Niedermayer, R. L. Byer, K. J. Leedle, O. Solgaard, arXiv:2310.02434

Contacts for media:

Chair for Laser Physics

Dr. Tomáš Chlouba

Phone: + 49 9131/85-27889

tomas.chlouba@fau.de

Dr. Roy Shiloh

Phone: + 49 9131/85-27211

roy.shiloh@fau.de

Stefanie Kraus

Phone: + 49 9131/85-28874

steffi.kraus@fau.de

Leon Brückner

Phone: + 49 9131/85-28319

leon.brueckner@fau.de

Prof. Dr. Peter Hommelhoff

Phone: + 49 9131/85-27090

peter.hommelhoff@fau.de

Wissenschaftliche Ansprechpartner:

Chair for Laser Physics

Dr. Tomáš Chlouba

Phone: + 49 9131/85-27889

tomas.chlouba@fau.de

Dr. Roy Shiloh

Phone: + 49 9131/85-27211

roy.shiloh@fau.de

Stefanie Kraus

Phone: + 49 9131/85-28874

steffi.kraus@fau.de

Leon Brückner

Phone: + 49 9131/85-28319

leon.brueckner@fau.de

Prof. Dr. Peter Hommelhoff

Phone: + 49 9131/85-27090

peter.hommelhoff@fau.de

Originalpublikation:

https://www.nature.com/articles/s41586-023-06602-7

https://www.fau.eu/2023/10/18/news/research/milestone-miniature-particle-accelerator-works/

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Faster, more energy-efficient way to manufacture an industrially important chemical

Zirconium combined with silicon nitride enhances the conversion of propane — present in natural gas — needed to create in-demand plastic, polypropylene. Polypropylene is a common type of plastic found…

Energy planning in Ghana as a role model for the world

Improving the resilience of energy systems in the Global South. What criteria should we use to better plan for resilient energy systems? How do socio-economic, technical and climate change related…

Artificial blood vessels could improve heart bypass outcomes

Artificial blood vessels could improve heart bypass outcomes. 3D-printed blood vessels, which closely mimic the properties of human veins, could transform the treatment of cardiovascular diseases. Strong, flexible, gel-like tubes…