Thermoelectric cooling gets fit for micro technology

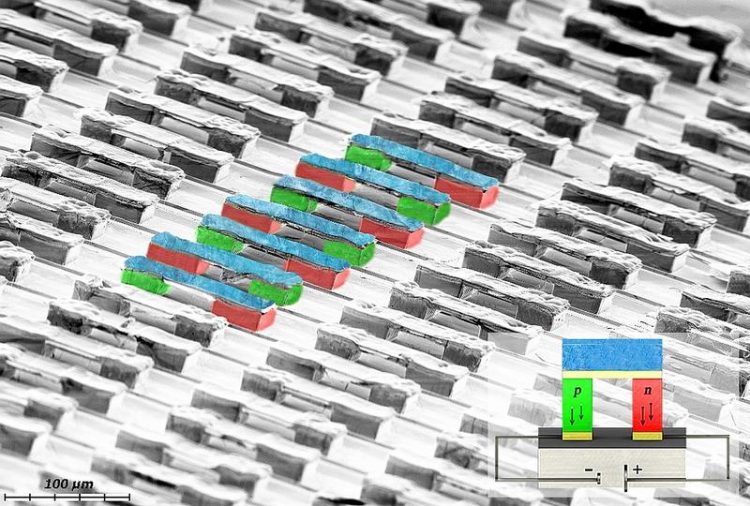

Array of micro-thermoelectric devices with a packing density of about 5,000 pieces per square centimeter. The free-standing design reduces thermo-mechanical stress.

Thermoelectric materials can convert heat into electricity or, vice versa, can be used as environmentally friendly cooling elements.

In many processes in everyday life and in industry, energy losses occur in form of waste heat, which can be converted by thermoelectric generators into electrical energy. This also provides an additional power source in these systems.

Another particularly attractive application of thermoelectric materials is the cooling of microelectronic components, for example in processors or for thermal management in organ implants. For this purpose, thermoelectric generators must be suitable for integration into modern microelectronic systems.

In addition, the manufacturing process must be compatible into the established processes of chip production. All this has proven challenging, so that a broad application of micro thermoelectric devices has not been realized so far.

Now there is a promising new approach by researchers at the Leibniz Institute for Solid State and Materials Research Dresden (IFW). They introduced a crucial innovation in the deposition process of the thermoelectric bismuth tellurium compound.

An additional gold electrolyte bath immediately after the layer deposition forms a protective gold layer on the thermoelectric elements. This interface significantly reduces the resistance between the thermoelectric material and the contact layer, which has a very positive effect on the efficiency and the functional stability in the long-term test.

The micro-thermoelectric devices processed in this way offer a very fast cooling response times of only one millisecond and a high reliability of more than 10 million cycles and more than 30 days of stable cooling performance. The improvement of these figures represents a decisive step towards the broad application of thermoelectric components.

Dr. Gabi Schierning

g.schierning@ifw-dresden.de

IFW Dresden

Phone: +49 (0) 351 4659 1875

Guodong Li, Javier Garcia Fernandez, David Alberto Lara Ramos, Vida Barati, Nicolás Pérez, Ivan Soldatov, Heiko Reith, Gabi Schierning & Kornelius Nielsch. Integrated micro thermoelectric coolers with rapid response time and high device reliability, Nature Electronics, volume 1 (2018) https://doi.org/10.1038/s41928-018-0148-3

Media Contact

More Information:

http://www.ifw-dresden.deAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…