Keeping Vilsmeier reagent in the flow

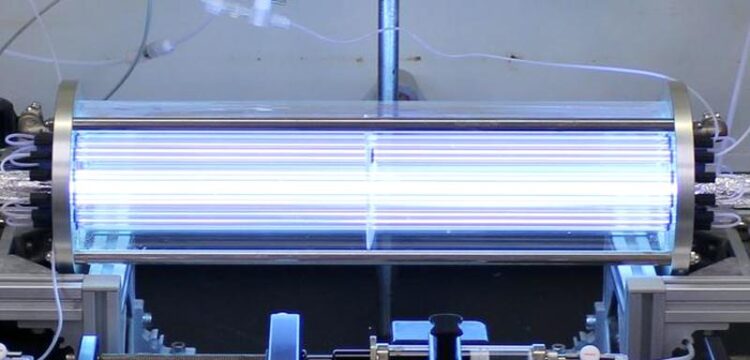

A unique flow UV reactor is the key to producing the Vilsmeier reagent’s toxic precursor on demand and from relatively stable and safe reactants. The scalable flow system lets the reagent react directly with any desired substrate to produce a wide range of useful chemicals.

Credit: TSUDA Akihiko

From toxin to medicine in one go.

The Vilsmeier reagent is necessary for producing a large range of pharmaceuticals, but its unstable nature and toxic precursor phosgene are challenges for its use. A new process that efficiently produces phosgene, the Vilsmeier reagent and the desired products in one flow is poised to make the industry greener and safer.

For the production of many active pharmaceutical ingredients, a chemical called Vilsmeier reagent is necessary, but it is extremely unstable. That’s why it is produced on-site and on-demand wherever possible. In addition, the currently used methods for producing the reagent either use phosgene, which is itself an unstable and highly toxic chemical, or if phosgene is avoided result in toxic or difficult-to-remove by-products.

Kobe University chemist TSUDA Akihiko specializes on on-demand systems and using a unique UV-radiation approach, his group previously achieved the production of both phosgene and the Vilsmeier reagent from relatively safe and stable starting chemicals directly in the same vessel as their intended reaction substrates. This means they could achieve the whole reaction as if phosgene or the Vilsmeier reagent were never there. And while their technique was at first limited by being a batch process and thus being not easily scalable, they recently developed a completely novel flow system for the production of phosgene, creating an opportunity for the scalable on-demand production of other chemicals requiring phosgene. Tsuda explains: “Our group discovered for the first time that chloroform, a common organic solvent, underwent photochemical oxidation to form phosgene with high efficiency when irradiated with ultraviolet light. Our ‘photo-on-demand organic synthesis method’ based on this chemical reaction is a big step for phosgene-based organic synthesis.”

In a study now published in the journal Organic Process Research & Development, the group adapted their unique process to create a flow system that produces the Vilsmeier reagent on demand from phosgene for direct reaction with any desired substrate. The phosgene was itself produced in the same on-demand flow system from chloroform, a relatively safe and stable starting compound, thus creating a scalable, safe and efficient reaction system to produce a wide range of useful chemicals.

“This reaction system consumes less energy, produces less waste, and enables versatile as well as scalable chemical synthesis. These features contribute positively to the life cycle assessment of the products, which is especially important in the industry,” comments Tsuda on the significance of this development. Thus, this process is a huge step into the direction of a safer and greener production of pharmaceutical chemicals. In addition, it also enables a more local production of these key chemicals, reducing dependence on production abroad.

Journal: Organic Process Research & Development

DOI: 10.1021/acs.oprd.3c00267

Method of Research: Experimental study

Subject of Research: Not applicable

Article Title: Flow Photo-on-Demand Synthesis of Vilsmeier Reagent and Acyl Chlorides from Chloroform and its Applications to Continuous Flow Synthesis of Carbonyl Compounds

Article Publication Date: 15-Sep-2023

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Faster, more energy-efficient way to manufacture an industrially important chemical

Zirconium combined with silicon nitride enhances the conversion of propane — present in natural gas — needed to create in-demand plastic, polypropylene. Polypropylene is a common type of plastic found…

Energy planning in Ghana as a role model for the world

Improving the resilience of energy systems in the Global South. What criteria should we use to better plan for resilient energy systems? How do socio-economic, technical and climate change related…

Artificial blood vessels could improve heart bypass outcomes

Artificial blood vessels could improve heart bypass outcomes. 3D-printed blood vessels, which closely mimic the properties of human veins, could transform the treatment of cardiovascular diseases. Strong, flexible, gel-like tubes…