Process to produce fiber composite components – Near-net-shape fabrics in preforms

For a cost-efficient mass production of fiber composite components, it is essential to optimize the preparation of the near-net-shape textile preforms. The actual process consists of the manufacturing of standard textile semi-finished materials and therefore results in a discontinuous and cost-extensive procedure. The several working-steps – cutting to form, handling and fixing of the parts – are time-consuming and generate a big loss of valuable material. The process object of this invention takes advantages on the use of near-net-shape fabrics. Here single textile reinforcement elements are joined in a continuous process to form the final preform. The process described increase significantly the productivity of the production process of preforms and constitutes therefore a basis for the serial production of fiber composite components. Furthermore this technology can be integrated in an existing chain process in order to upgrade it. On behalf of the RWTH Aachen, PROvendis offers the license to the technology and the possibility to establish a scientific cooperation for further development.

Further information: PDF

PROvendis GmbH

Phone: +49 (0)208/94105 10

Contact

Dipl.-Ing. Alfred Schillert

As Germany's association of technology- and patenttransfer agencies TechnologieAllianz e.V. is offering businesses access to the entire range of innovative research results of almost all German universities and numerous non-university research institutions. More than 2000 technology offers of 14 branches are beeing made accessable to businesses in order to assure your advance on the market. At www.technologieallianz.de a free, fast and non-bureaucratic access to all further offers of the German research landscape is offered to our members aiming to sucessfully transfer technologies.

Media Contact

All latest news from the category: Technology Offerings

Newest articles

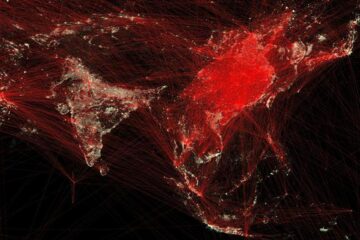

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

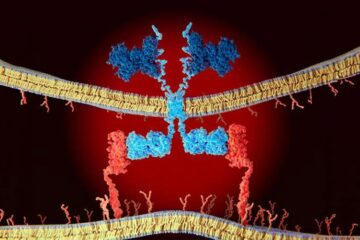

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…