Photonics: Integrated laser on silicon is looking good

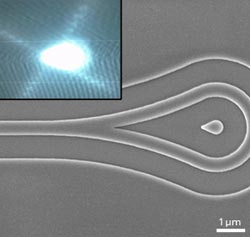

Scanning electron microscope image of the silicon-based micro-loop mirror. Light entering the waveguide from the left is guided around the loop and redirected back into the laser structure. The inset shows the laser spot photographed with an infrared camera. Copyright : A*STAR<br>

Active optical fibers with silicon photonic chips can carry a lot more information for data interconnect than copper cables. Silicon photonics can also be the material of choice for wiring 'lab-on-a-chip' devices — however, the construction of such devices is not without its challenges. One of the greatest difficulties is the implementation of lasers because silicon is a poor light emitter, but is commonly required for a photonic system on chip.

Doris Keh-Ting Ng at the A*STAR Data Storage Institute and co-workers have now successfully fabricated a laser on top of a silicon chip1. The III-V semiconductor materials are bonded to silicon to provide optical gain and the laser has a unique mirror design that promises enhanced device operation compared to the conventional feedback mirrors based on device facets.

“Integrated Si/III-V lasers can take advantage of low-loss silicon waveguides, while addressing the problem of low light emission efficiency that silicon devices typically have,” says Ng. Attaching a Si/III-V laser on top of silicon requires challenging fabrication techniques, and device performances can suffer as a result. Furthermore, any laser requires mirrors to maintain lasing action. Typically, such designs rely on the interface between air and the semiconductor, that is, the facets of the chip. These mirrors are not perfect and further reduce operation efficiency.

To improve on the latter aspect, the researchers have now come up with a unique mirror design, known as a micro-loop mirror (MLM). Light emitted from one end of the laser is guided along the waveguide, around a narrow bend and is then directed back into the device (see image). The mirror at the other end of the device is still formed by the interface with air, so that laser radiation can exit the device. The MLM achieves a remarkable 98% reflection efficiency of light. Such low losses mean that the MLM laser is comparatively efficient.

The successful demonstration of this technique is remarkable, considering that more than 30 fabrication steps are needed to fabricate the device, and in view of the fact that the MLM requires delicate and high-precision fabrication. The researchers aim to further enhance the laser, for example, by miniaturizing the device.

“Further improvements, for example, at the interface between the mirror and the lasing structure itself could lead to even better performance,” says Ng. “Laser with lower threshold and higher output power can possibly be achieved, leading to a potential solution to develop high-speed and low-cost optical communications and interconnects on electronics chips.”

The A*STAR-affiliated researchers contributing to this research are from the Data Storage Institute

Media Contact

More Information:

http://www.research.a-star.edu.sgAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…