Making ultrafast lasers faster

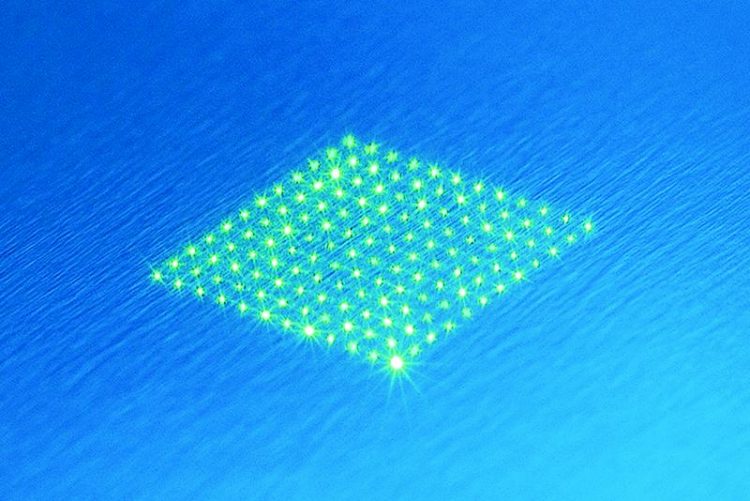

Array of multi-beams for parallelized ultrafast laser processing. © Fraunhofer ILT, Aachen, Germany

Ultrashort pulsed (USP) or ultrafast lasers can do something very unique: They ablate almost any material without causing a thermal load of the adjacent material.

Their cuts are smooth and melt-free, even on a micron scale. All of this makes ultrafast lasers very interesting for industries such as tool making, where hard materials must be processed very precisely.

In recent years, much progress has been made in developing ultrafast laser sources: Lasers with higher average power, higher pulse energy or higher repetition rate have become available.

They have been complemented by beam delivery systems, either based on ultrafast scanners or some special diffractive optical elements (DOE), that spread one beam into a pattern of many identical beamlets.

Although laser sources and beam delivery systems have improved remarkably, there is still room to grow, in particular when it comes to high-power lasers and high-efficiency processing technology.

The optical dot-matrix printer

A consortium of six partners from industry and research is now planning the next step in the development of the USP-laser process technology.

They will develop a powerful 1 kW laser source and combine it with a special optical system that delivers a pattern of more than 60 switchable beamlets. One can see this as a late descendant of the dot-matrix printer.

The consortium consists of the research institute Fraunhofer ILT and the RWTH Aachen University from Germany as well as Amplitude Systèmes, LASEA France, AA Opto-Electronic from France and LASEA from Belgium as industrial research and development partners.

The European Commission is supporting the project, named “MultiFlex”, within the framework of the program ICT-04-2018 for three years with an amount of € 4.7 million.

Delivery: High-end system ready for industrial use

The partners are looking beyond the already challenging system components: They intend to deliver a prototype with all the necessary control technology ready for the shop floor. It will start with a 1 kW laser machine that can deliver up to 1 mJ pulse energy either at the regular 1 MHz repetition rate or in a burst mode with less than 20 ns pulse separation.

The optical system converts the single laser beam into a pattern of more than 60 beamlets, where each single beamlet can be turned on and off separately. The resulting pattern can be directed onto the workpiece with a fast scanner. The complex system will be complemented by an industry grade control unit.

The resulting prototype will undergo an extensive series of tests and be validated in use cases provided by associated industrial end users. It has already been estimated that the prototype will improve the productivity by about 100 fold compared to current standard ultrafast laser processing systems.

This will not only allow for significant progress in the tool making industry, but also opens up new perspectives for the application of ultrafast lasers for the texturing and functionalization of large surfaces.

Funding

This project receives funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 825201.

Dr. Johannes Finger

Group Micro- and Nano Structuring

Telephone +49 241 8906-472

johannes.finger@ilt.fraunhofer.de

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…