A better understanding of soft artificial muscles

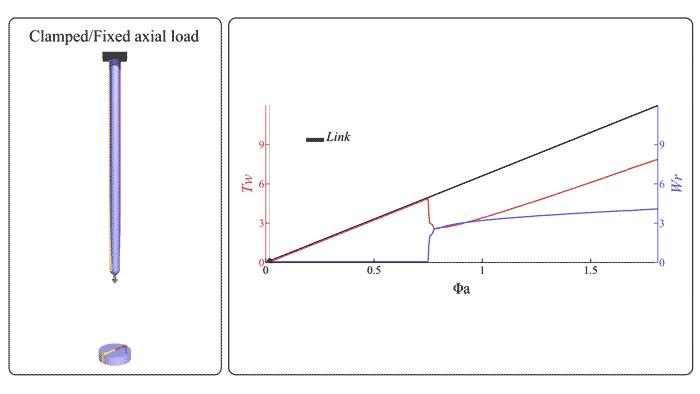

A filament is clamped at the top end and prestretched by a small amount by applying a downward axial load to the bottom end. The bottom end is then twisted, keeping the axial load on the bottom end constant. After a critical amount of twist is inserted, the filament spontaneously buckles into a loopy. Credit: Nicholas Charles/Harvard SEAS

Artificial muscles will power the soft robots and wearable devices of the future. But more needs to be understood about the underlying mechanics of these powerful structures in order to design and build new devices.

Now, researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have uncovered some of the fundamental physical properties of artificial muscle fibers.

“Thin soft filaments that can easily stretch, bend, twist or shear are capable of extreme deformations that lead to knot-like, braid-like or loop-like structures that can store or release energy easily,” said L. Mahadevan, the Lola England de Valpine Professor of Applied Mathematics, of Organismic and Evolutionary Biology, and of Physics.

“This has been exploited by a number of experimental groups recently to create prototypical artificial muscle fibers. But how the topology, geometry and mechanics of these slender fibers come together during this process was not completely clear. Our study explains the theoretical principles underlying these shape transformations, and sheds light on the underlying design principles.”

“Soft fibers are the basic unit of a muscle and could be used in everything from robotics to smart textiles that can respond to stimuli such as heat or humidity,” said Nicholas Charles, a PhD student in Applied Mathematics and first author of the paper.

“The possibilities are endless, if we can understand the system. Our work explains the complex morphology of soft, strongly stretched and twisted fibers and provides guidelines for the best designs.”

The research is published in Physical Review Letters.

Soft fibers, or filaments, can be stretched, sheared, bent or twisted. How these different actions interact to form knots, braids, and helices is important to the design of soft actuators. Imagine stretching and twisting a rubber band as tight as you can.

As the twist gets tighter and tighter, part of the band will pop out of the plane and start twisting around itself into a coil or knot. These coils and loops, in the right form, can be harnessed to actuate the knotted fiber.

The researchers found that different levels of stretch and twist result in different types of complex non-planar shapes. They characterized which shapes lead to kinked loops, which to tight coils, and which to a mixture of the two. They found that pre-stretch is important for forming coils, as these shapes are the most stable under stretching, and modeled how such coils can be used to produce mechanical work.

“This research gives us a simple way to predict how soft filaments will respond to twisting and stretching,” said Charles.

“Going forward, our work might also be relevant in other situations involving tangled filaments, as in hair curls, polymer dynamics and the dynamics of magnetic field lines in the sun and other stars,” said Mahadevan.

###

This research was co-authored by Mattia Gazzola, Assistant Professor of Mechanical Sciences and Engineering at the University of Illinois, and a former member of the group. It was supported in part by the National Science Foundation.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…