Machines that Can Feel / Sensitive Machine Components with Laser Technology

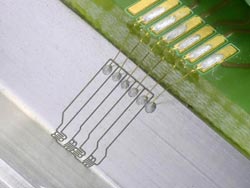

Laser-structured strain gauges in a groove in a machine component<br>

An isolating layer and a sensor layer are coated directly onto the tooling component, and the sensor is then structured using an ultrashort pulsed laser. Since masks are not necessary, these robust, high-quality thin-film sensors can be economically produced in small and medium-sized lots.

Scientists use a trick to make the slightest strain on parts of a tooling machine visible. They can measure stress on the fly, or recognize a dull cutting tool at an early stage. The Laser Zentrum Hannover e.V. (LZH) will show how this stress gauge works at this year’s Hannover Messe, from April 8th to 12th.

How can information on the condition of a tooling machine or process forces and vibrations be monitored during the manufacturing process, and even more important, how can this information be used for process optimization? This information can be measured using sensor modules with gentelligent (genetic + intelligent) components, which help a machine “feel”. This is the goal of a special research area “653” under the leadership of the Institute for Production Engineering and Machine Tools, University of Hannover, together with the LZH.

However, it is not simple to build such sensors. Tooling machines are usually very rigid, so that processing stresses cause only minimal deformation or distortion. In order to be able to measure these deformations precisely, the engineers used a “trick”. They placed strain gauges in the bottom of grooves in the machine components, where stresses are highest, and where stress gauges can make the most precise measurements.

However, up to now, it was not possible to place strain gauges in the bottom of grooves, as they are very difficult to access, and structures are usually complicated. Photolithographic sensors can only be used for flat surfaces, and strain gauges on foils, which are fixed to the machine using adhesives, are not suitable for the rough conditions in manufacturing processes.

The group “Laser-Micromachining” at the LZH used a laser structuring process to develop an innovative sensor for complex, three-dimensional tooling components. An isolating layer and a sensor layer are coated directly onto the tooling component, and the sensor is then structured using an ultrashort pulsed laser, with lateral resolutions from 10 to 100 µm. A laser scanner is used to ensure a fast structuring process. Since masks are not necessary, these high-quality thin-film sensors can be economically produced in small and medium-sized lots.

First prototypes of these laser structured sensors have already been integrated in the Z-axis slides of a tooling machine. Strain tests have shown that the sensors can measure even the smallest stresses, down to 0.001%.

Visitors to the LZH Stand at the Hannover Messe (Hall 17, Stand E 67) can test the function of these laser structured strain gauges themselves.

The work took place within the framework of the SFB project “Gentelligent Components in Life Cycle”, and have been financed by the German Research Foundation (DFG) since July, 2005.

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover, Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…