The materials engineers are developing environmentally friendly materials

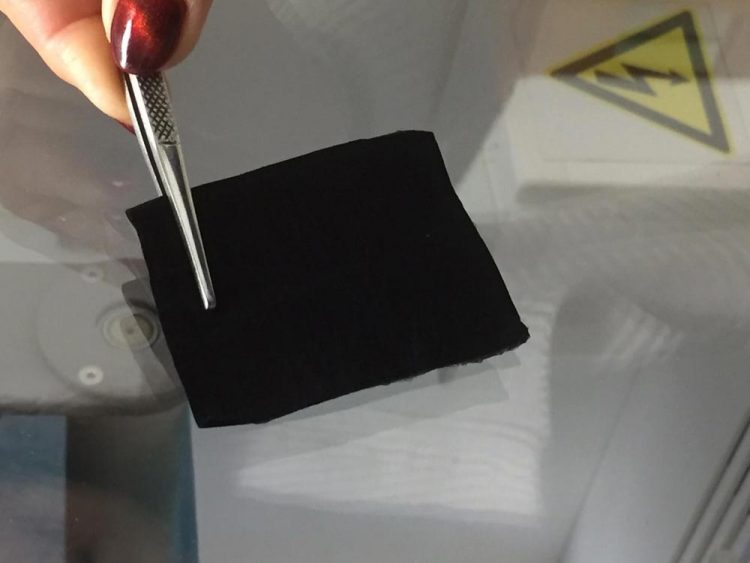

Original raw material of smart fabric Credit: TalTech University

Recently the research article “A method for producing conductive graphene biopolymer nanofibrous fabrics by exploitation of an ionic liquid dispersant in electrospinning” written by the researchers of Tallinn University of Technology was published in a leading peer-reviewed journal Carbon.

The article introduces nanofibers, a material produced by the electrospinning device at the Laboratory of Polymers and Textile Technology in Tallinn University of Technology, and their expanding range of applications. It is not possible to produce fibers with a diameter smaller than a micrometer by using conventional fiber spinning methods. Therefore, electrospinning technology is introduced, by which nanofibers are created by applying high voltage to polymer solution.

The beginning of the 20th century can be considered to be the starting point of electrospinning as a scientific discipline, the quest for industrial applications started 50 years ago. In recent years, there has been a surge of interest in electrospinning. One of the co-authors of the research article, Head of the Laboratory of Polymers and Textile Technology of Tallinn University of Technology, Professor Andres Krumme says, “The electrospun carbon nanomaterial can also be called smart fabric.

The nanofibers forming the material are 100 times thinner in diameter than hair, being however extremely strong, tough, flexible and due to carbon content also conductive. The material allows efficient energy storage owing to its high speci?c surface area.”

The specific properties of nanofibers render it a promising material for future applications:

- In environmental protection the non-woven fabric made of nanofibers can be used to clean contaminated air or water from fine particulate matter and heavy metals. In agriculture the smart fabric can be used e.g. as a shade cloth for plants to keep away insect pests (which is, of course, more effective than the existing shade cloths).

- In medicine the nanofabric can, due to the environment similar to the natural environment of a human body, be used to grow cells and produce antibacterial plasters and bandages. Nanofibers can be used to create cell culture media (stem cells are seeded on a biopolymer mat) and the grown stem cells can then be transplanted e.g. to damaged human skin.

- In clothing industry nanofibrous materials can be used to produce special protective clothing containing energy saving and collecting fibers (the collected energy can be used e.g. to charge a mobile phone). Nanofibrous electrodes with enhanced mechanical properties can be used as components of smart clothing to monitor and affect the health condition of the wearer. Garment sensors provide information about the wearer's needs as well as potential emergency situations (rescuers, fishermen, etc.).

“Cellulose used as the original raw material of smart fabric is very acceptable for human body due to its properties, i.e. the raw material used in polymer fabric is bio-based and supports the natural carbon cycle,” Andres Krumme says.

###

Source: Carbon, 2018 https:/

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…