Rare-earth innovation to improve nylon manufacturing

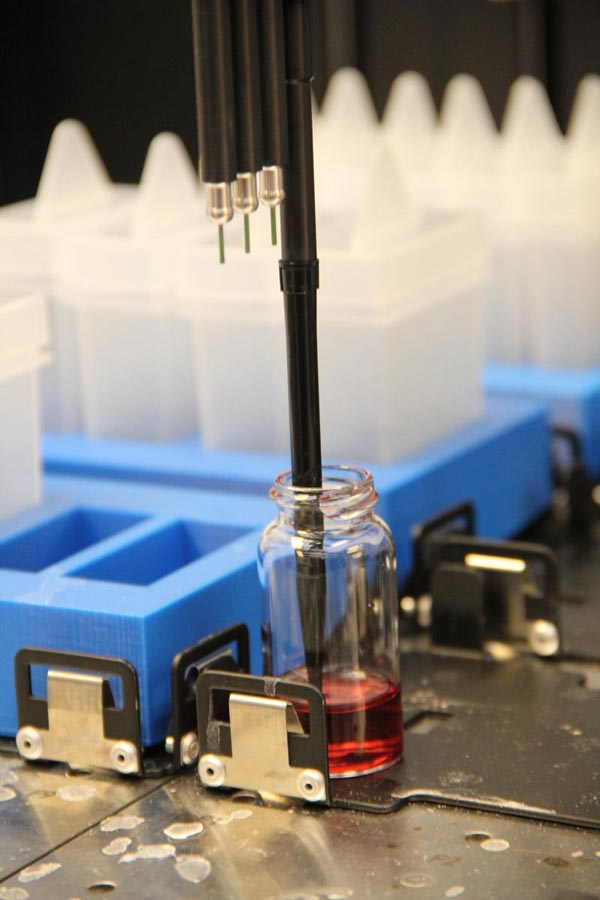

Scientists at the Critical Materials Institute at Ames Laboratory have created a new chemical process that makes use of widely available rare-earth metal cerium to improve the manufacture of nylon. Credit: U.S. Dept. of Energy's Ames Laboratory

The process uses a cerium-based material made into nanometer-sized particles with a palladium catalyst to produce cyclohexanone, a key ingredient in the production of nylon.

Traditional methods of producing cyclohexanone involve high temperatures and high pressure, and necessitate the use of hydrogen.

“After a lot of trials, we managed to find a reaction that works very well at room temperature and ambient pressure,” said CMI and Ames Laboratory scientist Igor Slowing. “That's a huge advantage cost-wise. It's more energy efficient, and requires much less hydrogen.”

The discovery is a rather unique way that CMI is addressing global concerns about the supply and demand of rare-earth metals.

“The research group focused on three or four different catalytic reactions used in high production volume chemicals, including this one for producing a precursor to nylon, which as an industry has enormous applications,” said Slowing, who is also an adjunct assistant professor of chemistry at Iowa State University.

“We are the only CMI scientists looking at catalysis, and so we are looking at this problem from a different angle. While other scientists are trying to find ways to use less of the least abundant rare-earths, we are trying to find ways to use more of the most abundant ones.”

At first that seems counter-intuitive to the research mission of CMI, which includes reducing reliance on rare-earth materials.

But rare-earth metals like cerium, which is as abundant as copper, are primary products of mining for other, more valuable rare-earth elements. With minimal demand for these abundant rare earths, they are stockpiled. Finding widely marketable uses for these stock-piled materials makes the best use of all mining resources, and improves the economic feasibility of mining overall.

Slowing said the technology also has other possible applications, like the treatment of biomass.

###

The technology is discussed in the paper “Selective Hydrogenation of Phenol Catalyzed by Palladium on High Surface Ceria at Room Temperature and Ambient Pressure,” by a team that also included Nicholas C. Nelson, Sebastian Manzano, and Aaron D. Sadow from Ames Laboratory, Steven Overbury from Oak Ridge National Laboratory, and was published in ACS Catalysis

The Critical Materials Institute is a Department of Energy Innovation Hub led by the U.S. Department of Energy's Ames Laboratory. CMI seeks ways to eliminate and reduce reliance on rare-earth metals and other materials critical to the success of clean energy technologies.

Ames Laboratory is a U.S. Department of Energy Office of Science national laboratory operated by Iowa State University. Ames Laboratory creates innovative materials, technologies and energy solutions. We use our expertise, unique capabilities and interdisciplinary collaborations to solve global problems.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

New insights into the mechanisms of chromosome segregation errors

Research on centromere structure… Researchers from the Kops group in collaboration with researchers from the University of Edinburgh, made a surprising new discovery in the structure of the centromere, a structure…

“Topological hall effect” in two-dimensional quantum magnets

In a recent study published in Nature Physics, researchers from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, together with researchers of University of Science and Technology of China, have introduced the…

Coating Technologies of the Future

LZH and Cutting Edge Coatings at Optatec… At Optatec 2024, the Laser Zentrum Hannover e.V. (LZH) and Cutting Edge Coatings GmbH (CEC) present new opportunities in coating technologies for the…