Design and validation of world-class multilayered thermal emitter using machine learning

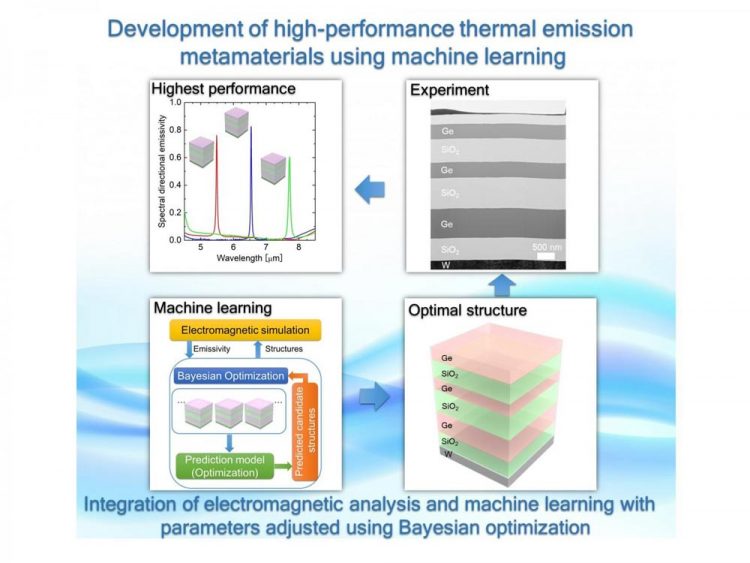

Schematic diagram showing the materials informatics method combining machine learning and the calculation of thermal emission properties and experiments conducted to verify the performance of fabricated materials. Credit: NIMS

NIMS, the University of Tokyo, Niigata University and RIKEN jointly designed a multilayered metamaterial that realizes ultra-narrowband wavelength-selective thermal emission by combining the machine learning (Bayesian optimization) and thermal emission properties calculations (electromagnetic calculation).

The joint team then experimentally fabricated the designed metamaterial and verified the performance. These results may facilitate the development of highly efficient energy devices.

Thermal radiation, a phenomenon that an object emits heat as electromagnetic waves, is potentially applicable to a variety of energy devices, such as wavelength-selective heaters, infrared sensors and thermophotovoltaic generators. Highly efficient thermal emitters need to exhibit emission spectrum with narrow bands in practically usable wavelength range.

The development of such efficient thermal emitters has been targeted by many researches using metamaterials that can manipulate electromagnetic waves. However, most of them have taken an approach of characterizing the material structures selected empirically. , it has been difficult to identify the optimum structure from a vast number of candidates.

The joint research group developed a method of designing metamaterial structures with optimum thermal radiation performance using a combination of machine learning and the calculation of thermal emission properties. This project focused on easy-to-fabricate multilayered metamaterial structures composed of three types of materials in 18 layers of varying thickness.

Application of this method to about eight billion candidate structures led to the prediction that a nanostructure composed of non-periodically arranged semiconductor and dielectric materials would have superior thermal radiation performance, which was contrary to the conventional knowledge.

Then the research group actually fabricated the metamaterial structure and measured its thermal emission spectrum, and consequently demonstrated an extremely narrow thermal emission band.

Measured in terms of the Q-factor (a parameter used to measure the width of thermal emission spectral bands), the newly designed nanostructure produced a Q-factor close to 200, when 100 had been considered the upper limit for conventional materials?an exceptionally narrow thermal emission spectral band.

This research demonstrated the effectiveness of machine learning in developing highly efficient thermal emission metamaterials. The development of metamaterials with desirable thermal emission spectra is expected to facilitate more efficient energy use throughout the society. Because the nanostructure design method developed is applicable to all kinds of materials, it may serve as an effective tool for the design of high-performance materials in the future.

###

This research project was carried out by a research group led by Junichiro Shiomi (Professor, Department of Mechanical Engineering, The University of Tokyo) Atsushi Sakurai (Associated Professor, Department of Mechanical and Production Engineering, Niigata University) and Koji Tsuda (Professor, Graduate School of Frontier Sciences, The University of Tokyo). The part of this project conducted at the CMI2 (Center for Materials Research by Information Integration) was supported by the JST “Materials Research by Information Integration” Initiative (MI2I), while the remainder of this project, conducted at the RIKEN Center for Advanced Intelligence Project (AIP), was supported by funding from MEXT.

This study was published in ACS Central Science, an online U.S. journal, as an “ASAP article” on January 22, 2019, Eastern Standard Time.

###

Contacts

(Regarding this research)

Junichiro Shiomi

Professor, Department of Mechanical Engineering, The University of Tokyo;

Special Researcher, Center for Materials Research by Information Integration (CMI2), National Institute for Materials Science;

Visiting Scientist, RIKEN Center for Advanced Intelligence Project

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

Tel: +81-3-5841-6283, Fax: +81-3-5841-0440

Email: shiomi@photon.t.u-tokyo.ac.jp

Atsushi Sakurai

Associate Professor, Department of Mechanical and Production Engineering, Niigata University;

Special Researcher, Center for Materials Research by Information Integration (CMI2), National Institute for Materials Science

2-8050 Ikarashi, Nishi-ku, Niigata 950-2181, Japan

Tel: +81-25-262-7004, Fax: +81-25-262-7004

Email: sakurai@eng.niigata-u.ac.jp

(Regarding JST projects)

COI Group

Department of Innovation Platform

Japan Science and Technology Agency

K's Gobancho, 7 Gobancho, Chiyoda-ku, Tokyo 102-8666, Japan

Tel: +81-3-6267-4752, Fax: +81-3-5214-8496

Email: ihub@jst.go.jp

(For general inquiries)

Public Relations Office

National Institute for Materials Sciences

Tel: +81-29-859-2026

Fax: +81-29-859-2017

E-Mail: pressrelease=ml.nims.go.jp

(Please change “=” to “@”)

Public Relations Office

School of Engineering

The University of Tokyo

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

Tel: +81-3-5841-1790, Fax: +81-3-5841-0529

Email: kouhou@pr.t.u-tokyo.ac.jp

Public Relations Office

Graduate School of Frontier Sciences

The University of Tokyo

Tel: +81-4-7136-5450

Email: taguchi.yumie@edu.k.u-tokyo.ac.jp

Public Relations Office

Niigata University

2-8050 Ikarashi, Nishi-ku, Niigata 950-2181, Japan

Tel: +81-25-262-7000, Fax: +81-25-262-6539

E-mail: pr-office@adm.niigata-u.ac.jp

Public Relations Office

RIKEN

Tel: +81-48-467-9272, Fax: +81-48-462-4715

Email: ex-press@riken.jp

Public Relations Division

Japan Science and Technology Agency

5-3 Yonbancho, Chiyoda-ku, Tokyo 102-8666, Japan

Tel: +81-3-5214-8404, Fax: +81-3-5214-8432

Email: jstkoho@jst.go.jp

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…